Rising Demand for Automation

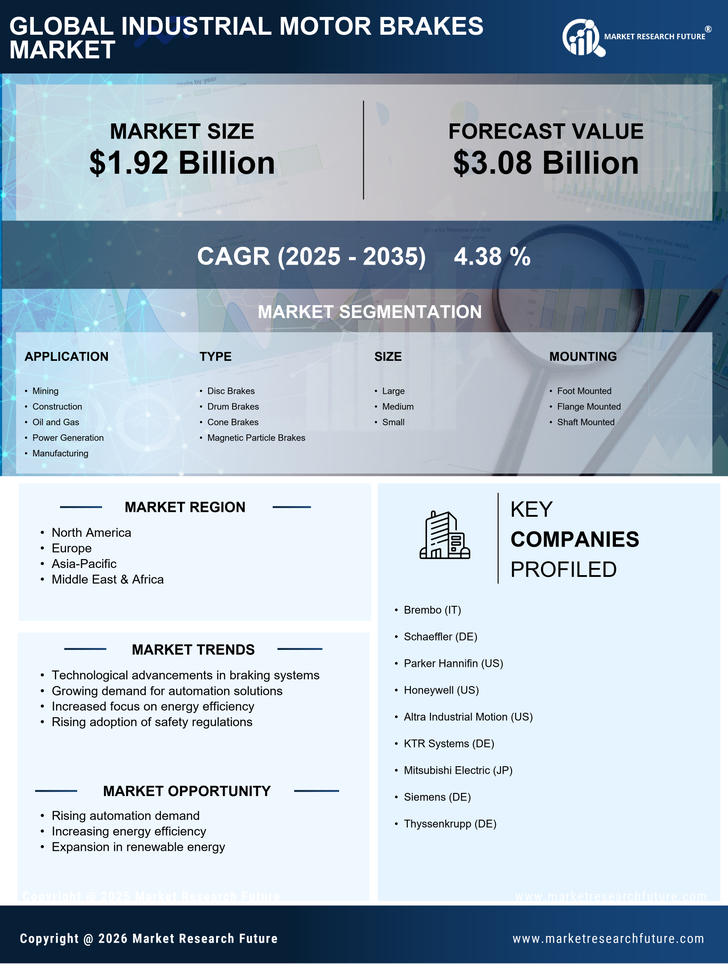

The Industrial Motor Brakes Market is experiencing a notable surge in demand due to the increasing adoption of automation across various sectors. Industries such as manufacturing, logistics, and construction are integrating automated systems to enhance efficiency and productivity. This trend is reflected in the projected growth of the automation market, which is expected to reach USD 300 billion by 2025. As automation systems require reliable braking solutions to ensure safety and operational efficiency, the demand for industrial motor brakes is likely to rise correspondingly. Furthermore, the need for precision in automated processes necessitates advanced braking technologies, thereby driving innovation within the Industrial Motor Brakes Market.

Growth in Renewable Energy Sector

The Industrial Motor Brakes Market is poised to benefit from the expansion of the renewable energy sector. As countries increasingly invest in wind and solar energy, the demand for industrial motor brakes in these applications is expected to grow. Wind turbines, for instance, require robust braking systems to ensure safety during high winds and maintenance operations. The Industrial Motor Brakes Market is projected to reach USD 2 trillion by 2025, indicating a substantial opportunity for the Industrial Motor Brakes Market. This growth not only highlights the importance of reliable braking systems in renewable energy applications but also suggests a shift towards more sustainable practices within the industry.

Increased Focus on Safety Regulations

The Industrial Motor Brakes Market is significantly influenced by the heightened focus on safety regulations across various industries. Governments and regulatory bodies are implementing stringent safety standards to minimize workplace accidents and ensure the safe operation of machinery. This regulatory environment compels manufacturers to invest in high-quality braking systems that comply with safety standards. As a result, the demand for advanced industrial motor brakes is likely to increase, as companies seek to enhance safety measures. The market for industrial motor brakes is projected to grow at a compound annual growth rate of 5% through 2025, driven by these regulatory requirements and the need for improved safety in industrial operations.

Technological Innovations in Braking Systems

The Industrial Motor Brakes Market is witnessing a wave of technological innovations that are transforming braking systems. Advancements in materials science and engineering are leading to the development of more efficient and durable braking solutions. For instance, the introduction of smart braking systems equipped with sensors and automation capabilities is enhancing performance and reliability. These innovations not only improve the operational efficiency of machinery but also reduce maintenance costs. The market for smart braking systems is expected to grow significantly, with estimates suggesting a potential increase of 20% by 2025. This trend indicates a shift towards more sophisticated braking technologies within the Industrial Motor Brakes Market.

Expansion of Manufacturing and Construction Sectors

The Industrial Motor Brakes Market is benefiting from the expansion of the manufacturing and construction sectors. As these industries continue to grow, the demand for reliable braking systems in machinery and equipment is increasing. The manufacturing sector alone is projected to reach USD 5 trillion by 2025, driven by technological advancements and increased production capacities. This growth necessitates the use of industrial motor brakes to ensure the safe and efficient operation of machinery. Additionally, the construction sector's ongoing projects require robust braking solutions for heavy equipment, further propelling the demand within the Industrial Motor Brakes Market. This trend underscores the critical role of industrial motor brakes in supporting industrial growth.