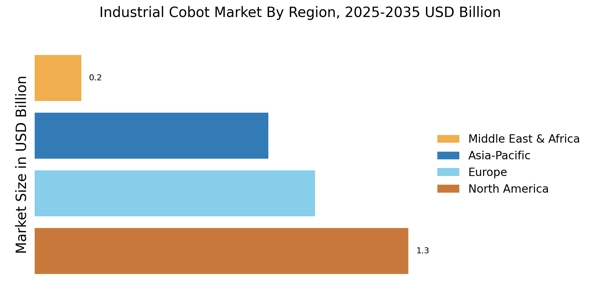

North America : Automation Leader

North America is the largest market for industrial cobots, holding approximately 40% of the global market share. The region's growth is driven by increasing automation in manufacturing, a skilled workforce, and supportive government policies promoting robotics. The demand for collaborative robots is further fueled by the need for efficiency and safety in production environments, particularly in sectors like automotive and electronics. The United States leads the North American market, with significant contributions from Canada and Mexico. Key players such as Universal Robots, FANUC, and ABB are actively expanding their presence. The competitive landscape is characterized by innovation and partnerships, with companies focusing on developing user-friendly and versatile cobots to meet diverse industry needs. The region's robust infrastructure and investment in R&D also play a crucial role in maintaining its leadership in the cobot market.

Europe : Innovation and Sustainability

Europe is the second-largest market for industrial cobots, accounting for around 30% of the global share. The region's growth is propelled by a strong emphasis on sustainability, innovation, and the integration of Industry 4.0 technologies. European governments are actively supporting automation initiatives through funding and regulatory frameworks, which enhance the adoption of collaborative robots across various sectors, including manufacturing and logistics.

Germany, France, and the UK are the leading countries in this market, with Germany being the largest contributor. The competitive landscape features major players like KUKA and ABB, who are investing in advanced cobot technologies. The presence of numerous startups focusing on niche applications also enriches the industrial cobot market size. The European market is characterized by a collaborative ecosystem, where companies, research institutions, and governments work together to drive innovation in robotics.

Asia-Pacific : Emerging Market Potential

Asia-Pacific is rapidly emerging as a significant player in the industrial cobot market, holding approximately 25% of the global share. The region's growth is driven by increasing labor costs, a shift towards automation, and government initiatives promoting robotics in manufacturing. Countries like China and Japan are at the forefront, with substantial investments in technology and infrastructure to support the adoption of collaborative robots. China is the largest market in the region, followed by Japan and South Korea. The competitive landscape is marked by both established companies like Yaskawa and FANUC and a growing number of local startups. The presence of key players is bolstered by strategic partnerships and collaborations aimed at enhancing product offerings. The region's focus on innovation and cost-effective solutions positions it well for future growth in the cobot sector.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa (MEA) region is gradually recognizing the potential of industrial cobots, currently holding about 5% of the global market share. The growth in this region is driven by increasing investments in automation, particularly in sectors like oil and gas, manufacturing, and logistics. Governments are beginning to implement policies that encourage the adoption of advanced technologies, which is expected to catalyze industrial cobot market size growth in the coming years.

Countries such as the UAE and South Africa are leading the way in cobot adoption, with initiatives aimed at enhancing productivity and efficiency. The competitive landscape is still developing, with a mix of international players and local firms. Key players are exploring opportunities to enter the market, focusing on tailored solutions that meet the unique needs of the region. As awareness of the benefits of cobots grows, the MEA market is poised for significant expansion.