India Metal Forging Market Summary

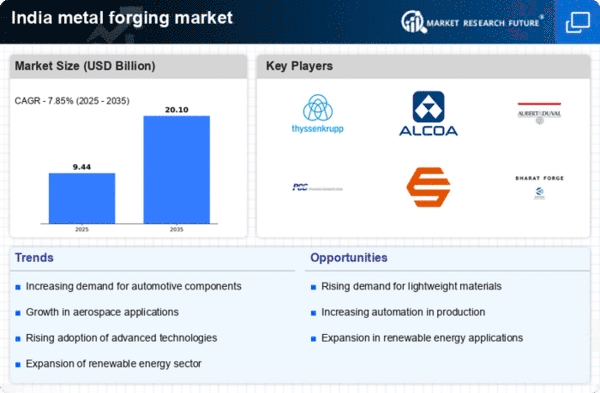

As per Market Research Future analysis, the India metal forging market Size was estimated at 8.75 USD Billion in 2024. The India metal forging market is projected to grow from 9.44 USD Billion in 2025 to 20.1 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 7.8% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The India metal forging market is poised for robust growth driven by technological advancements and increasing demand from key industries.

- Technological advancements are reshaping the metal forging landscape, enhancing efficiency and precision.

- The automotive sector remains the largest segment, while aerospace manufacturing is emerging as the fastest-growing segment.

- Sustainability initiatives are gaining traction, reflecting a broader industry shift towards environmentally friendly practices.

- Key market drivers include the growth of the automotive sector and infrastructure development initiatives, which are fueling demand for forged components.

Market Size & Forecast

| 2024 Market Size | 8.75 (USD Billion) |

| 2035 Market Size | 20.1 (USD Billion) |

| CAGR (2025 - 2035) | 7.85% |

Major Players

Thyssenkrupp AG (DE), Alcoa Corporation (US), Aubert & Duval (FR), Precision Castparts Corp. (US), Forged Solutions Group (GB), Bharat Forge Limited (IN), Friedrich Kocks GmbH & Co. KG (DE), Nippon Steel Corporation (JP), Shaanxi Blower (CN)