Cost Reduction in Launch Services

The In Space Manufacturing Market is poised for growth as the cost of launching payloads into space continues to decline. Recent advancements in reusable rocket technology have significantly lowered the expenses associated with space missions. This reduction in launch costs is likely to encourage more companies to consider in-space manufacturing as a viable option. With launch costs potentially dropping by up to 50% in the next few years, the economic feasibility of producing goods in space becomes more attractive. As a result, the In Space Manufacturing Market may see an influx of new players and innovative projects, further expanding its reach and capabilities.

Government Support and Investment

Government initiatives and funding are playing a crucial role in the growth of the In Space Manufacturing Market. Various countries are recognizing the strategic importance of space capabilities and are investing in research and development to foster innovation in this sector. For instance, funding programs aimed at supporting private space ventures are becoming more common, with budgets allocated for in-space manufacturing projects. This support not only enhances technological advancements but also encourages collaboration between public and private sectors. As government backing continues to strengthen, the In Space Manufacturing Market is likely to benefit from increased resources and opportunities for development.

Emerging Applications in Healthcare

The In Space Manufacturing Market is witnessing a burgeoning interest in healthcare applications, particularly in the production of pharmaceuticals and medical devices in microgravity. Research indicates that certain drugs manufactured in space exhibit improved efficacy and reduced side effects, which could revolutionize treatment options on Earth. As the healthcare sector increasingly explores the potential of in-space manufacturing, investments in this area are expected to rise. The market for space-based healthcare products could reach several hundred million USD by 2028, highlighting the transformative potential of the In Space Manufacturing Market in addressing medical challenges.

Sustainability and Resource Utilization

Sustainability is becoming a pivotal driver in the In Space Manufacturing Market, as the focus shifts towards utilizing space resources for manufacturing processes. The concept of in-situ resource utilization (ISRU) is gaining traction, where materials from celestial bodies, such as asteroids or the Moon, are harnessed for production. This approach not only reduces the need for transporting materials from Earth but also aligns with global sustainability goals. As technologies for ISRU develop, the In Space Manufacturing Market may see a significant transformation, potentially leading to a more sustainable and efficient manufacturing paradigm in space.

Increased Demand for Space-Based Products

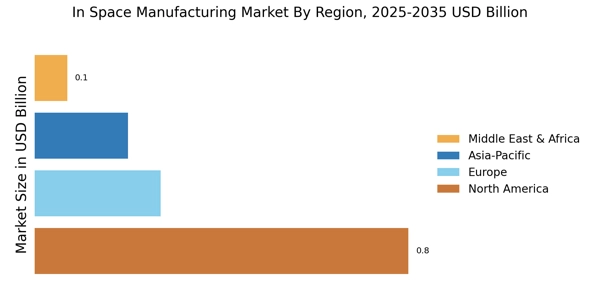

The In Space Manufacturing Market is experiencing a notable surge in demand for space-based products, driven by advancements in technology and the growing interest in space exploration. As private companies and government agencies invest heavily in space missions, the need for materials and components that can be manufactured in microgravity is becoming increasingly apparent. This shift is expected to create a market valued at approximately 1.5 billion USD by 2027, as more entities recognize the potential benefits of producing items such as satellites and pharmaceuticals in space. The unique properties of materials produced in microgravity can lead to enhanced performance and efficiency, further fueling interest in the In Space Manufacturing Market.