Growth in Automotive Sector

The automotive sector is a critical driver for the Impregnating Resins Market, as manufacturers increasingly utilize these resins for various applications. The shift towards electric vehicles and hybrid models necessitates advanced materials that can withstand higher temperatures and provide superior insulation. Impregnating resins are utilized in the production of electric motor components, ensuring optimal performance and longevity. The automotive industry is projected to witness a growth rate of around 4% annually, which directly correlates with the rising demand for impregnating resins. As automotive manufacturers prioritize lightweight and efficient materials, the Impregnating Resins Market is likely to see a corresponding increase in demand, further solidifying its position within the automotive supply chain.

Expansion of Renewable Energy Sources

The transition towards renewable energy sources is significantly influencing the Impregnating Resins Market. As the world shifts focus to sustainable energy solutions, the demand for high-quality insulating materials in wind turbines and solar panels is on the rise. Impregnating resins play a crucial role in enhancing the performance and durability of these renewable energy systems. The market for renewable energy is expected to grow at a rate of approximately 8% annually, which will likely drive the demand for impregnating resins. This growth is attributed to the increasing investments in renewable energy infrastructure and the need for reliable materials that can withstand harsh environmental conditions. Thus, the Impregnating Resins Market stands to gain from this expanding sector, as manufacturers seek to provide innovative solutions for renewable energy applications.

Increasing Focus on Energy Efficiency

The growing emphasis on energy efficiency across various industries is a significant driver for the Impregnating Resins Market. As companies strive to reduce energy consumption and enhance operational efficiency, the demand for materials that contribute to these goals is rising. Impregnating resins are essential in manufacturing energy-efficient electrical components, as they improve insulation and reduce energy losses. The market for energy-efficient products is projected to expand at a rate of around 6% annually, which will likely boost the demand for impregnating resins. This trend is particularly evident in sectors such as construction and manufacturing, where energy-efficient solutions are increasingly prioritized. Consequently, the Impregnating Resins Market is well-positioned to capitalize on this growing focus on energy efficiency.

Rising Demand in Electrical Applications

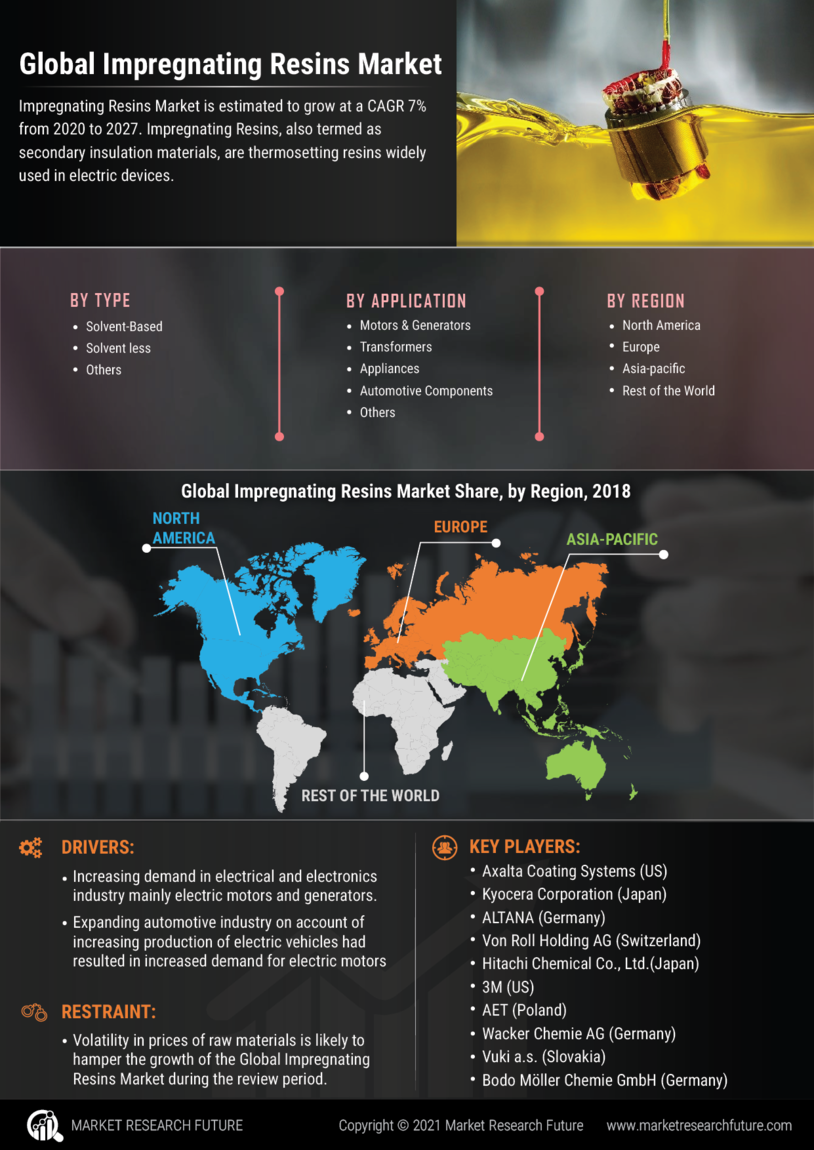

The Impregnating Resins Market is experiencing a notable surge in demand, particularly within electrical applications. As industries increasingly rely on advanced electrical components, the need for high-performance insulating materials becomes paramount. Impregnating resins, known for their excellent dielectric properties, are essential in enhancing the durability and efficiency of electrical devices. The market for electrical insulation materials is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years, indicating a robust demand for impregnating resins. This growth is driven by the expansion of renewable energy sectors and the increasing adoption of electric vehicles, which require reliable insulation solutions. Consequently, the Impregnating Resins Market is poised to benefit significantly from these trends, as manufacturers seek to meet the evolving needs of the electrical sector.

Technological Innovations in Material Science

Technological advancements in material science are reshaping the Impregnating Resins Market. Innovations in resin formulations and processing techniques are leading to the development of more efficient and effective impregnating resins. These advancements enable manufacturers to produce resins with enhanced thermal stability, chemical resistance, and electrical insulation properties. The introduction of smart materials and nanotechnology is also paving the way for new applications in various industries, including electronics and automotive. As the demand for high-performance materials continues to rise, the Impregnating Resins Market is likely to benefit from these technological innovations. The ongoing research and development efforts in this field suggest a promising future for impregnating resins, as they become integral to next-generation applications.