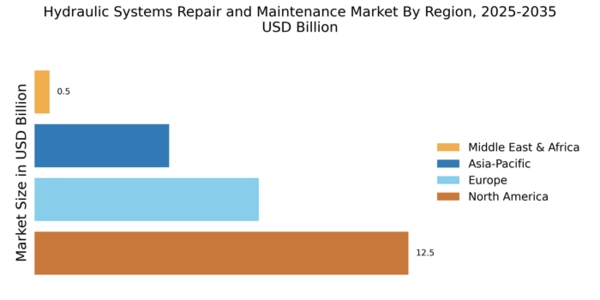

North America : Market Leader in Hydraulic Services

North America is poised to maintain its leadership in the Hydraulic Systems Repair and Maintenance market, holding a significant market share of 12.5 in 2024. The growth is driven by increasing industrial automation, stringent safety regulations, and a rising demand for efficient hydraulic systems. The region's robust infrastructure and technological advancements further bolster market expansion, making it a key player in the global landscape.

The United States stands out as the leading country, hosting major players like Parker Hannifin, Eaton, and Moog. The competitive landscape is characterized by innovation and strategic partnerships among key players, ensuring a steady supply of advanced hydraulic solutions. The presence of established companies and a skilled workforce contribute to the region's dominance in hydraulic repair services.

Europe : Innovation and Sustainability Focus

Europe's Hydraulic Systems Repair and Maintenance market is projected to reach a size of 7.5 by 2025, driven by a strong emphasis on sustainability and innovation. Regulatory frameworks promoting energy efficiency and environmental protection are key catalysts for market growth. The increasing adoption of advanced hydraulic technologies in various industries, including manufacturing and construction, is also contributing to the rising demand for repair and maintenance services.

Germany and France are leading countries in this region, with a competitive landscape featuring major players like Bosch Rexroth and Hydac. The market is characterized by a mix of established companies and emerging startups focusing on innovative solutions. The European market is also witnessing collaborations aimed at enhancing service delivery and customer satisfaction, ensuring a robust growth trajectory.

Asia-Pacific : Emerging Market with Growth Potential

The Asia-Pacific region is experiencing rapid growth in the Hydraulic Systems Repair and Maintenance market, projected to reach 4.5 by 2025. This growth is fueled by increasing industrialization, urbanization, and a rising demand for efficient hydraulic systems across various sectors. Government initiatives aimed at enhancing infrastructure and manufacturing capabilities are also significant drivers of market expansion in this region.

China and India are the leading countries in this market, with a competitive landscape that includes both local and international players. Companies like Danfoss and Sauer-Danfoss are making significant inroads, focusing on innovative solutions tailored to regional needs. The presence of a large workforce and growing investments in technology further enhance the region's potential in hydraulic repair services.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region, with a market size of 0.5, presents untapped opportunities in the Hydraulic Systems Repair and Maintenance sector. The growth is driven by increasing investments in infrastructure and industrial projects, alongside a rising demand for efficient hydraulic systems. Regulatory support for industrial development is also fostering a conducive environment for market expansion in this region.

Countries like South Africa and the UAE are emerging as key players, with a competitive landscape that includes both local and international firms. The presence of key players is gradually increasing, focusing on providing tailored solutions to meet regional demands. As the market matures, there is significant potential for growth in hydraulic repair services, driven by ongoing industrialization efforts.