North America : Market Leader in Repair Services

North America is poised to maintain its leadership in the Mining Hydraulic Equipment Repair and Maintenance Market, holding a significant market share of 2.6 billion. The region's growth is driven by increasing mining activities, stringent safety regulations, and a focus on equipment longevity. The demand for efficient repair services is further fueled by technological advancements and the need for sustainable practices in mining operations.

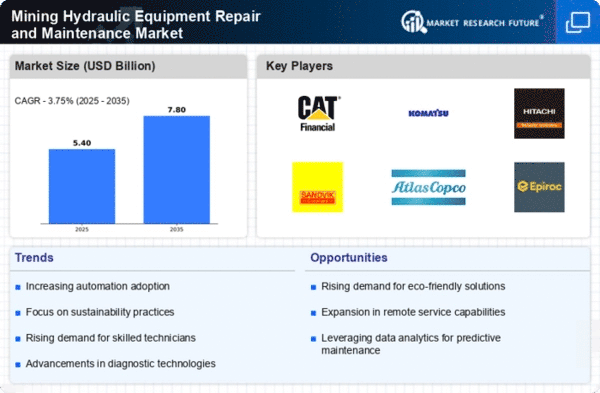

The competitive landscape is characterized by major players such as Caterpillar, Terex, and Volvo Construction Equipment, which dominate the market with their extensive service networks and innovative solutions. The U.S. and Canada are the leading countries, benefiting from robust infrastructure and investment in mining technologies. The presence of these key players ensures a steady supply of high-quality repair services, catering to the growing needs of the mining sector.

Europe : Emerging Market with Growth Potential

Europe's Mining Hydraulic Equipment Repair and Maintenance Market is valued at 1.4 billion, reflecting a growing demand for repair services driven by the region's commitment to sustainable mining practices and regulatory compliance. The European Union's stringent environmental regulations are catalyzing investments in equipment maintenance and repair, ensuring operational efficiency and compliance with safety standards.

Leading countries such as Germany, Sweden, and Finland are at the forefront of this market, supported by key players like Sandvik and Atlas Copco. The competitive landscape is evolving, with a focus on innovative repair solutions and enhanced service offerings. The presence of established companies and a growing emphasis on sustainability are expected to drive market growth in the coming years.

Asia-Pacific : Rapidly Growing Market Dynamics

The Asia-Pacific region, with a market size of 1.0 billion, is witnessing rapid growth in the Mining Hydraulic Equipment Repair and Maintenance Market. This growth is primarily driven by increasing mining activities in countries like China and Australia, coupled with rising demand for efficient repair services. The region's focus on modernizing mining operations and enhancing equipment reliability is further propelling market expansion.

Key players such as Komatsu and Hitachi Construction Machinery are actively investing in service capabilities to meet the growing demand. The competitive landscape is characterized by a mix of local and international companies, all striving to capture market share in this dynamic environment. As mining operations expand, the need for reliable repair services will continue to rise, positioning Asia-Pacific as a significant player in the global market.

Middle East and Africa : Emerging Market with Challenges

The Middle East and Africa region, with a market size of 0.2 billion, is in the early stages of developing its Mining Hydraulic Equipment Repair and Maintenance Market. The growth is driven by increasing investments in mining infrastructure and a rising demand for efficient repair services. However, challenges such as regulatory hurdles and limited access to advanced technologies hinder rapid market development.

Countries like South Africa and the UAE are leading the way, with a focus on enhancing their mining capabilities. The competitive landscape is still evolving, with a mix of local and international players. As the region continues to invest in mining, the demand for repair services is expected to grow, albeit at a slower pace compared to other regions.