Expansion of the Aerospace Sector

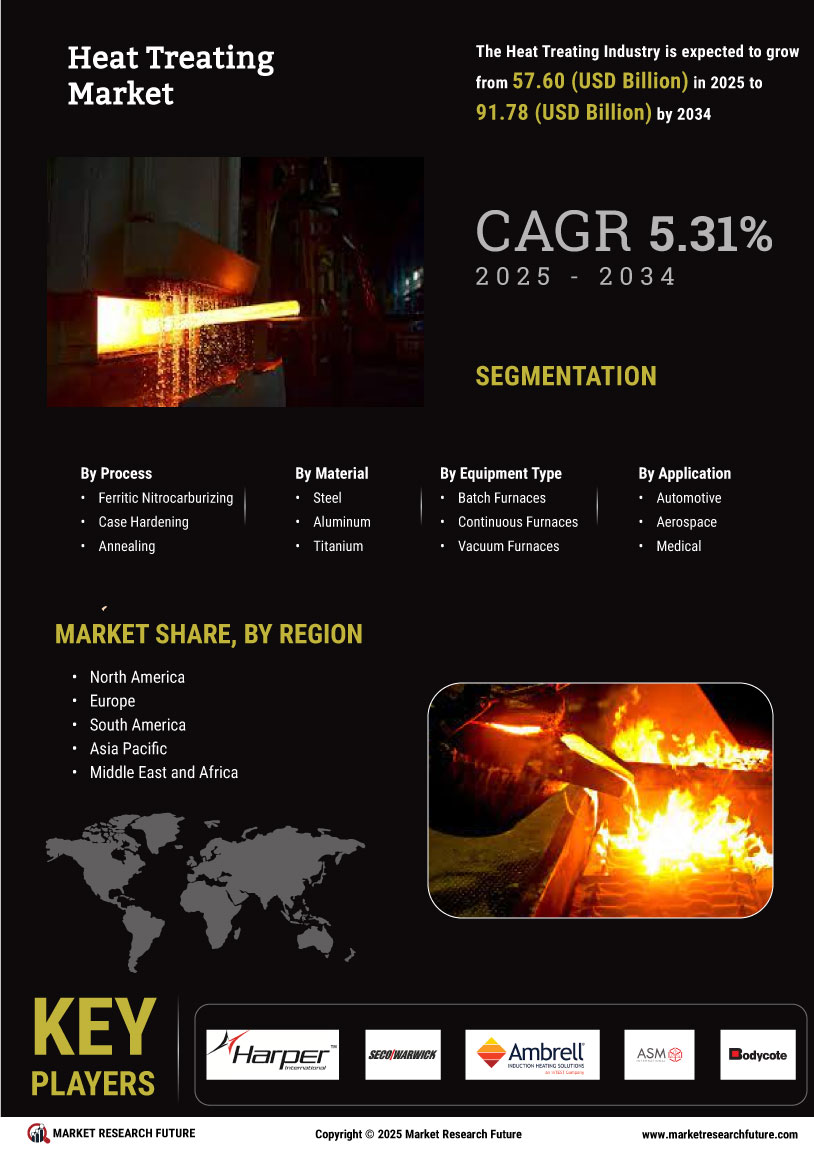

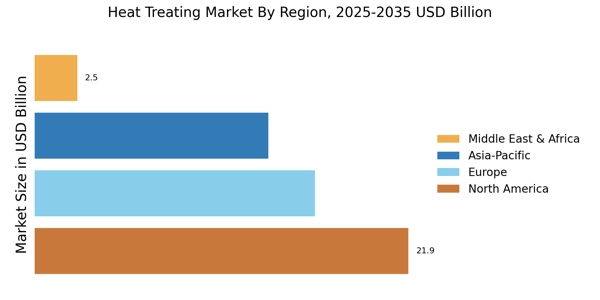

The aerospace sector's expansion significantly influences the Heat Treating Market, as the demand for lightweight and high-strength components continues to rise. With The Heat Treating Market projected to grow at a compound annual growth rate of around 5% over the next decade, the need for advanced heat treating processes becomes increasingly evident. Heat treating plays a crucial role in enhancing the mechanical properties of materials used in aircraft manufacturing, ensuring safety and performance. As aerospace manufacturers seek to innovate and improve fuel efficiency, the Heat Treating Market is likely to benefit from increased investments in heat treating technologies tailored for this sector.

Increased Focus on Energy Efficiency

Energy efficiency remains a critical concern within the Heat Treating Market, as manufacturers strive to reduce operational costs and environmental impact. The implementation of energy-efficient heat treating technologies, such as induction heating and vacuum heat treating, has gained traction. These methods not only minimize energy consumption but also enhance the quality of the treated materials. Reports suggest that energy-efficient processes can reduce energy usage by up to 30%, making them attractive to manufacturers aiming to optimize production. As industries increasingly adopt these technologies, the Heat Treating Market is likely to witness a shift towards more sustainable practices, aligning with broader environmental goals.

Rising Demand for High-Performance Materials

The Heat Treating Market experiences a notable surge in demand for high-performance materials across various sectors, including automotive, aerospace, and manufacturing. As industries increasingly prioritize durability and performance, the need for heat-treated components becomes paramount. For instance, the automotive sector is projected to witness a growth rate of approximately 4.5% annually, driven by the demand for lightweight and high-strength materials. This trend indicates that manufacturers are likely to invest in advanced heat treating processes to enhance the mechanical properties of materials, thereby ensuring safety and efficiency in their applications. Consequently, the Heat Treating Market is poised for expansion as companies seek to meet these evolving material requirements.

Growing Demand from the Tool and Die Industry

The tool and die industry significantly contributes to the Heat Treating Market, as the demand for durable and high-performance tools continues to rise. Heat treating processes are essential for enhancing the hardness and wear resistance of tools, which are critical for manufacturing precision components. With the tool and die market projected to grow steadily, driven by advancements in manufacturing technologies, the Heat Treating Market is likely to see increased demand for specialized heat treating services. This trend indicates a robust relationship between the two sectors, suggesting that as the tool and die industry evolves, so too will the requirements for heat treating solutions.

Technological Innovations in Heat Treating Processes

Technological innovations are reshaping the Heat Treating Market, with advancements in automation and process control enhancing efficiency and precision. The integration of Industry 4.0 technologies, such as IoT and AI, allows for real-time monitoring and optimization of heat treating processes. This shift not only improves product quality but also reduces waste and operational costs. As manufacturers increasingly adopt these technologies, the Heat Treating Market is expected to experience a transformation, characterized by enhanced productivity and reduced lead times. The potential for these innovations to streamline operations suggests a promising future for the industry.