Increasing Adoption in the Automotive Sector

The automotive sector significantly influences the Vacuum Heat Treatment Industry, as manufacturers seek to enhance the performance and longevity of vehicle components. Vacuum heat treatment processes improve the hardness and wear resistance of critical parts such as gears, shafts, and bearings. With the automotive industry increasingly focusing on lightweight materials and fuel efficiency, vacuum heat treatment offers a viable solution to meet these demands. The market's growth is further supported by the anticipated increase in vehicle production and the shift towards electric vehicles, which require high-performance components. This trend is expected to contribute to the market's expansion, reaching 4.69 USD Billion by 2035.

Growing Demand for High-Performance Materials

The Vacuum Heat Treatment Industry experiences a surge in demand for high-performance materials across various sectors, including aerospace, automotive, and electronics. As industries increasingly prioritize durability and performance, vacuum heat treatment processes enhance the mechanical properties of metals and alloys. This trend is particularly evident in the aerospace sector, where components must withstand extreme conditions. The market is projected to reach 3.04 USD Billion in 2024, reflecting a growing recognition of the benefits of vacuum heat treatment in producing reliable and efficient materials. Consequently, this demand is expected to drive innovation and investment in advanced heat treatment technologies.

Rising Focus on Energy Efficiency and Sustainability

The Global Vacuum Heat Treatment Industry is witnessing a rising focus on energy efficiency and sustainability, driven by global environmental concerns. Vacuum heat treatment processes are inherently more energy-efficient compared to traditional methods, as they operate in a controlled environment that minimizes energy loss. This efficiency aligns with the growing emphasis on reducing carbon footprints across industries. Furthermore, the ability to recycle materials and reduce waste during the heat treatment process enhances the sustainability profile of vacuum heat treatment. As industries adopt greener practices, the demand for vacuum heat treatment is likely to increase, positioning it as a key player in the transition towards sustainable manufacturing.

Technological Advancements in Heat Treatment Processes

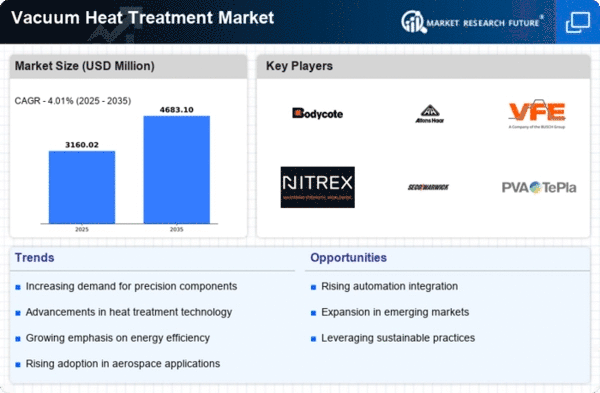

Technological advancements play a pivotal role in shaping the Vacuum Heat Treatment Industry. Innovations in equipment and processes enhance efficiency, reduce energy consumption, and improve the quality of treated materials. For instance, the integration of automation and smart technologies in vacuum furnaces allows for precise control over temperature and pressure, resulting in superior treatment outcomes. These advancements not only optimize production processes but also contribute to sustainability efforts by minimizing waste and energy usage. As a result, the market is likely to witness a compound annual growth rate of 4.01% from 2025 to 2035, driven by the continuous evolution of heat treatment technologies.

Regulatory Support for Advanced Manufacturing Technologies

Regulatory support for advanced manufacturing technologies significantly impacts the Vacuum Heat Treatment Industry. Governments worldwide are increasingly recognizing the importance of advanced manufacturing processes in enhancing competitiveness and innovation. Initiatives aimed at promoting research and development in heat treatment technologies are likely to foster growth in the vacuum heat treatment sector. Additionally, regulations encouraging the adoption of energy-efficient practices and materials further bolster market prospects. As industries align with these regulatory frameworks, the vacuum heat treatment market is expected to benefit from increased investments and technological advancements, paving the way for a more robust and competitive landscape.