Technological Innovations

Technological advancements play a pivotal role in shaping the Grinding Machinery Market. Innovations such as computer numerical control (CNC) technology, automation, and artificial intelligence are revolutionizing grinding processes. These technologies enhance precision, reduce cycle times, and improve overall efficiency. In 2025, the integration of smart technologies is expected to increase, with a projected market share of around 30% for automated grinding solutions. This shift towards automation not only streamlines operations but also minimizes human error, thereby elevating product quality. Additionally, advancements in material testing and grinding tools contribute to the development of more durable and efficient machinery. As manufacturers increasingly adopt these technologies, the Grinding Machinery Market is likely to witness substantial growth, driven by the demand for high-tech solutions that meet the evolving needs of various sectors.

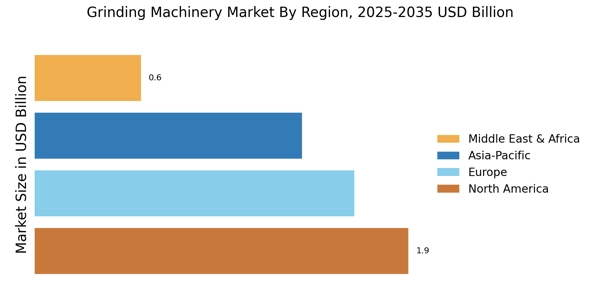

Expansion of End-User Industries

The expansion of end-user industries is a significant driver for the Grinding Machinery Industry. Sectors such as construction, mining, and energy are witnessing robust growth, leading to an increased demand for grinding machinery. In 2025, the construction industry alone is projected to grow at a rate of 6%, necessitating advanced grinding solutions for various applications. This growth is further supported by infrastructure development initiatives and rising investments in renewable energy projects. As these industries expand, the need for high-performance grinding machinery becomes critical to meet production demands. Additionally, the diversification of applications across different sectors is likely to create new opportunities for grinding machinery manufacturers. As end-user industries continue to flourish, the Grinding Machinery and Grinding machines for metal are expected to benefit from this upward trend, driving innovation and investment in advanced grinding technologies.

Rising Demand in Manufacturing Sector

The Grinding Machinery Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries such as automotive, aerospace, and electronics continue to grow, the need for precision grinding machinery becomes increasingly critical. In 2025, the manufacturing sector is projected to contribute significantly to the overall economic output, with estimates suggesting a growth rate of approximately 4.5% annually. This growth necessitates advanced grinding solutions that enhance productivity and efficiency, thereby propelling the Grinding Machinery forward. Furthermore, the increasing complexity of components in various applications requires sophisticated grinding technologies, which further fuels market demand. As manufacturers seek to optimize their operations, investments in high-performance grinding machinery are likely to rise, indicating a robust future for the Grinding Machinery.

Increasing Focus on Quality and Precision

Quality and precision are paramount in the Grinding Machinery Industry, particularly as industries strive for higher standards in manufacturing. The demand for precision-engineered components is escalating, with sectors such as aerospace and medical devices requiring stringent tolerances. In 2025, the market for precision grinding machinery is anticipated to grow by approximately 5%, reflecting the increasing emphasis on quality assurance. Manufacturers are investing in advanced grinding technologies that ensure consistent quality and reduce defects, thereby enhancing their competitive edge. This focus on quality not only drives the demand for sophisticated grinding machinery but also encourages innovation within the industry. As companies prioritize precision in their production processes, the Grinding Machinery is poised for growth, with a clear trajectory towards more advanced and reliable grinding solutions.

Sustainability and Environmental Regulations

The Grinding Machinery Market is increasingly influenced by sustainability initiatives and environmental regulations. As industries face mounting pressure to reduce their carbon footprint, the demand for eco-friendly grinding solutions is on the rise. In 2025, it is estimated that approximately 25% of manufacturers will prioritize sustainable practices in their operations. This shift is prompting the development of grinding machinery that minimizes waste and energy consumption. Furthermore, compliance with stringent environmental regulations is driving manufacturers to invest in technologies that align with sustainability goals. The adoption of energy-efficient grinding machines not only meets regulatory requirements but also enhances operational efficiency. As sustainability becomes a core focus for many industries, the Grinding Machinery is likely to evolve, with a growing emphasis on environmentally responsible practices and products.