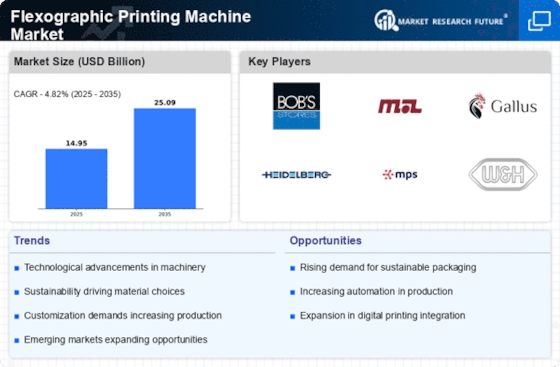

North America : Innovation and Demand Surge

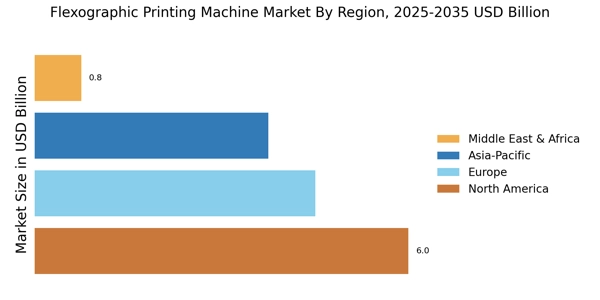

North America is the largest market for flexographic printing machines, holding approximately 40% of the global Flexographic Printing Machine Market share. The region's growth is driven by increasing demand for sustainable packaging solutions and advancements in printing technology. Regulatory support for eco-friendly practices further catalyzes market expansion, with companies investing in innovative solutions to meet consumer preferences for sustainable products.

The United States and Canada are the leading countries in this region, with a competitive landscape featuring key players like Mark Andy and Bobst. The presence of advanced manufacturing facilities and a strong focus on R&D contribute to the region's dominance. Additionally, partnerships between manufacturers and packaging companies enhance Flexographic Printing Machine Market growth, ensuring a steady supply of high-quality flexographic printing machines.

Europe : Sustainable Practices Drive Growth

Europe is the second-largest market for flexographic printing machines, accounting for around 30% of the global Flexographic Printing Machine Market share. The region's growth is propelled by stringent regulations promoting sustainable packaging and a shift towards eco-friendly materials. Countries like Germany and Italy are at the forefront, with increasing investments in advanced printing technologies and sustainable practices driving demand.

Germany, Italy, and the Netherlands are leading countries in this market, with key players such as Gallus and Heidelberg. The competitive landscape is characterized by innovation and collaboration among manufacturers to enhance product offerings. The European Flexographic Printing Machine Market is also witnessing a rise in small and medium enterprises adopting flexographic printing, further diversifying the competitive environment.

Asia-Pacific : Rapid Growth and Adoption

Asia-Pacific is witnessing rapid growth in the flexographic printing machine market, holding approximately 25% of the global market share. The region's expansion is driven by increasing urbanization, rising disposable incomes, and a growing demand for packaged goods. Countries like China and India are leading this growth, supported by favorable government policies and investments in manufacturing capabilities.

China is the largest Flexographic Printing Machine Market in the region, with significant contributions from local manufacturers and international players like MPS Systems and W&H. The competitive landscape is evolving, with a focus on technological advancements and cost-effective solutions. As the region continues to embrace modern printing technologies, the demand for flexographic machines is expected to rise significantly, catering to various industries including food and beverage, pharmaceuticals, and consumer goods.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region is gradually emerging in the flexographic printing machine market, holding about 5% of the global Flexographic Printing Machine Market share. The growth is driven by increasing industrialization, urbanization, and a rising demand for packaging solutions across various sectors. Countries like South Africa and the UAE are leading this growth, with investments in infrastructure and manufacturing capabilities supporting Flexographic Printing Machine Market expansion.

South Africa is the largest market in the region, with a competitive landscape that includes both local and international players. The presence of key manufacturers and distributors is enhancing market accessibility. As the region continues to develop, the demand for flexographic printing machines is expected to grow, driven by the need for efficient and high-quality printing solutions in packaging and labeling industries.