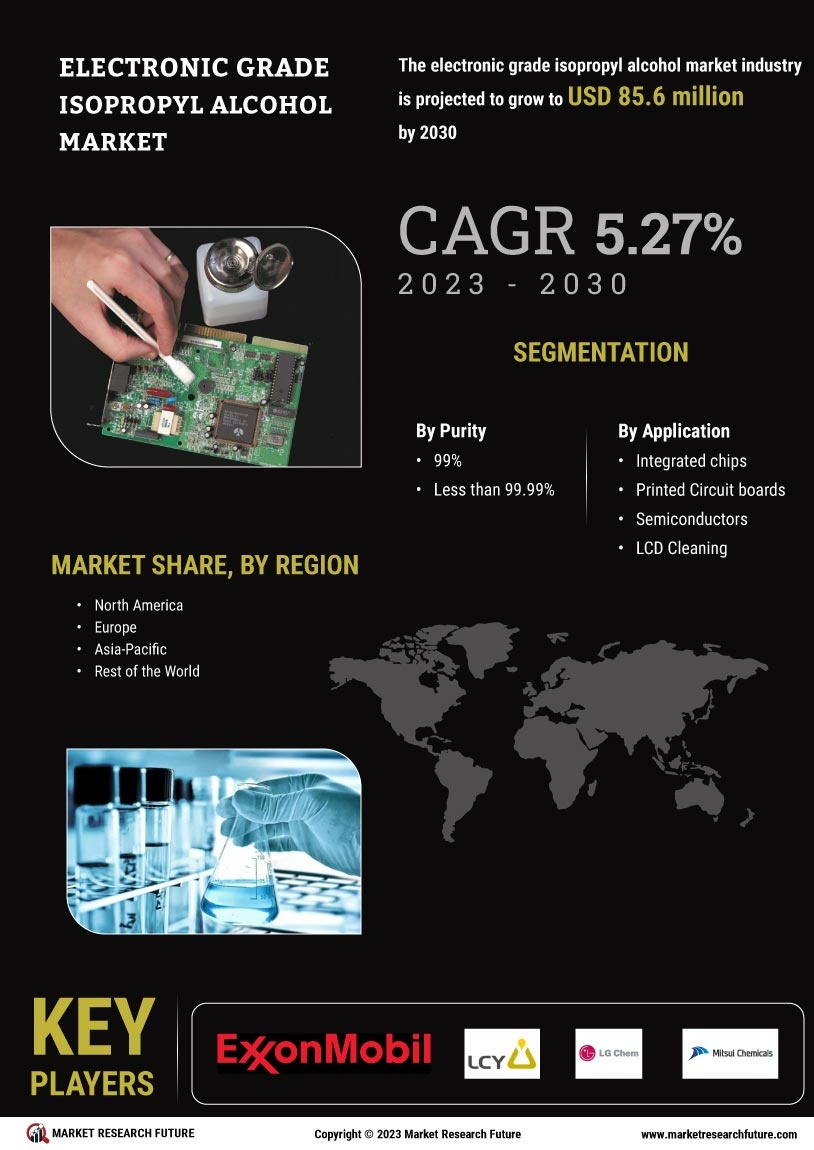

Expansion of the Electronics Sector

The rapid expansion of the electronics sector is a crucial driver for The Global Electronic Grade Isopropyl Alcohol Industry. With the proliferation of consumer electronics, including smartphones, tablets, and wearable devices, the demand for high-quality solvents is surging. This growth is further fueled by advancements in technologies such as 5G and the Internet of Things, which require sophisticated electronic components. As manufacturers strive to meet the increasing production demands, the need for electronic grade isopropyl alcohol becomes more pronounced. Market analysts predict that the electronics sector will continue to expand, thereby propelling the growth of The Global Electronic Grade Isopropyl Alcohol Industry in the coming years.

Focus on Environmental Sustainability

Environmental sustainability has emerged as a pivotal driver in The Global Electronic Grade Isopropyl Alcohol Industry. As regulatory frameworks tighten around chemical usage, manufacturers are increasingly adopting eco-friendly practices. This includes the development of bio-based isopropyl alcohol, which not only meets purity standards but also reduces the carbon footprint associated with traditional production methods. The market is witnessing a shift towards sustainable sourcing and production techniques, which could potentially enhance brand reputation and customer loyalty. Companies that prioritize sustainability may find themselves at a competitive advantage, as consumers and businesses alike become more environmentally conscious. This trend is likely to shape the future landscape of The Global Electronic Grade Isopropyl Alcohol Industry.

Rising Demand for High-Purity Solvents

The increasing need for high-purity solvents in various electronic applications drives The Global Electronic Grade Isopropyl Alcohol Industry. As semiconductor manufacturing processes become more intricate, the demand for solvents with minimal impurities escalates. This trend is particularly evident in the production of integrated circuits, where even trace contaminants can compromise product quality. The market for electronic grade isopropyl alcohol is projected to grow at a compound annual growth rate of approximately 6% over the next five years, reflecting the industry's shift towards higher purity standards. Manufacturers are responding by enhancing their purification processes to meet these stringent requirements, thereby expanding their market share in The Global Electronic Grade Isopropyl Alcohol Industry.

Technological Innovations in Production

Technological advancements in the production of electronic grade isopropyl alcohol are significantly influencing The Global Electronic Grade Isopropyl Alcohol Industry. Innovations such as advanced distillation techniques and membrane filtration are enhancing the efficiency and purity of the final product. These technologies not only reduce production costs but also minimize waste, aligning with the industry's sustainability goals. Furthermore, the integration of automation and real-time monitoring systems in manufacturing processes is expected to improve quality control, ensuring that the solvents meet the rigorous standards required for electronic applications. As these technologies continue to evolve, they may lead to increased market penetration and growth opportunities within The Global Electronic Grade Isopropyl Alcohol Industry.

Increasing Investment in Research and Development

Investment in research and development is playing a pivotal role in shaping The Global Electronic Grade Isopropyl Alcohol Industry. Companies are allocating substantial resources to innovate and improve the quality of electronic grade solvents. This focus on R&D is driven by the need to meet evolving industry standards and customer expectations. Enhanced formulations and production methods are being developed to ensure that isopropyl alcohol meets the stringent requirements of high-tech applications. Furthermore, collaborations between industry players and research institutions are fostering innovation, leading to the introduction of new products that cater to specific market needs. This trend is likely to sustain the growth momentum of The Global Electronic Grade Isopropyl Alcohol Industry.