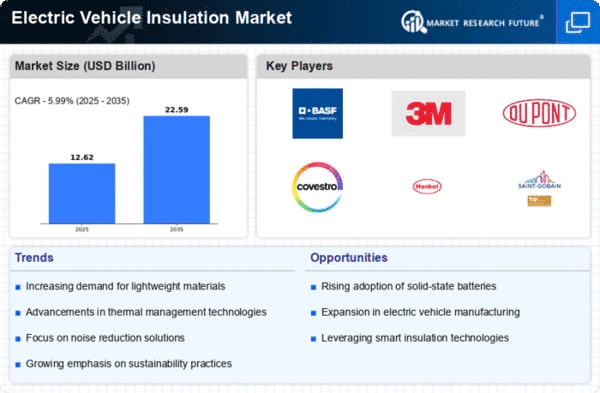

Market Growth Projections

The Global Electric Vehicle Insulation Market Industry is projected to experience substantial growth over the next decade. With an estimated market value of 11.2 USD Billion in 2024, it is anticipated to reach 22.6 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 6.56% from 2025 to 2035, indicating a robust demand for insulation materials as electric vehicle production scales up. The increasing focus on performance, safety, and sustainability in electric vehicles will likely drive innovations in insulation technologies, further enhancing market dynamics.

Regulatory Support and Incentives

Government regulations and incentives aimed at promoting electric vehicle adoption are crucial drivers for the Global Electric Vehicle Insulation Market Industry. Many countries are implementing stricter emissions standards and offering financial incentives for electric vehicle purchases. This regulatory support encourages manufacturers to invest in high-quality insulation solutions that enhance vehicle efficiency and safety. As a result, the insulation market is likely to benefit from increased demand for electric vehicles, further propelling its growth. The alignment of these policies with market trends indicates a favorable environment for insulation innovations in the coming years.

Expansion of Charging Infrastructure

The expansion of electric vehicle charging infrastructure is a vital driver for the Global Electric Vehicle Insulation Market Industry. As more charging stations are established globally, the demand for electric vehicles is likely to increase, leading to a corresponding rise in insulation needs. Effective insulation plays a critical role in ensuring the safety and efficiency of charging systems, which are essential for widespread electric vehicle adoption. This infrastructure development is expected to support the growth of the insulation market, as manufacturers seek to provide solutions that meet the evolving demands of the electric vehicle ecosystem.

Growing Demand for Electric Vehicles

The increasing global demand for electric vehicles is a primary driver for the Global Electric Vehicle Insulation Market Industry. As consumers become more environmentally conscious, the shift towards electric mobility accelerates. In 2024, the market is projected to reach 11.2 USD Billion, reflecting a significant investment in electric vehicle technology. This trend is expected to continue, with projections indicating the market could expand to 22.6 USD Billion by 2035. The need for effective insulation materials to enhance battery performance and thermal management is paramount, thereby driving innovation and growth in the insulation sector.

Focus on Energy Efficiency and Sustainability

The global emphasis on energy efficiency and sustainability is significantly influencing the Global Electric Vehicle Insulation Market Industry. As electric vehicles become a cornerstone of sustainable transportation, the demand for insulation materials that improve energy efficiency is rising. Manufacturers are increasingly focusing on developing eco-friendly insulation solutions that minimize environmental impact while maximizing performance. This shift not only aligns with consumer preferences but also meets regulatory requirements. The growing awareness of sustainability issues is expected to drive innovation in insulation technologies, thereby enhancing the overall market landscape.

Technological Advancements in Insulation Materials

Technological advancements in insulation materials are reshaping the Global Electric Vehicle Insulation Market Industry. Innovations such as lightweight composites and advanced thermal barriers are being developed to improve energy efficiency and safety in electric vehicles. These materials not only enhance the thermal management of batteries but also contribute to overall vehicle performance. As manufacturers strive to meet stringent safety regulations and consumer expectations, the adoption of these advanced materials is likely to increase. This trend suggests a robust growth trajectory for the insulation market, aligning with the anticipated CAGR of 6.56% from 2025 to 2035.