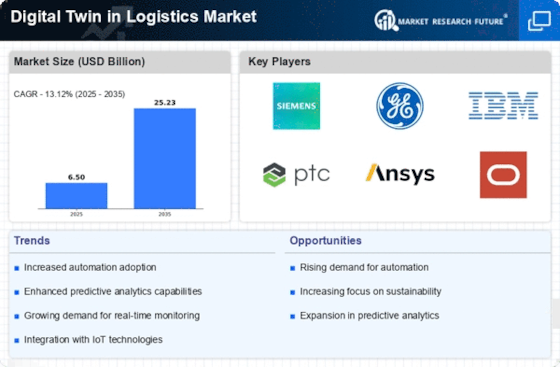

Rising Demand for Automation

The rising demand for automation in the logistics sector is a prominent driver in the Digital Twin In Logistic Market. As companies seek to reduce manual interventions and enhance productivity, digital twin technology plays a pivotal role in automating various logistics processes. By creating virtual models of operations, businesses can identify areas suitable for automation, leading to increased efficiency and reduced human error. Current trends indicate that the automation of logistics processes can lead to a 40% increase in operational speed. Consequently, the integration of digital twins is likely to accelerate as organizations aim to meet the growing demand for faster and more reliable logistics solutions.

Advancements in Data Analytics

The Digital Twin In Logistic Market is significantly influenced by advancements in data analytics. The integration of sophisticated analytics tools with digital twin technology enables logistics companies to derive actionable insights from vast amounts of data. This capability allows for predictive modeling and scenario analysis, which can enhance decision-making processes. Reports suggest that organizations leveraging data analytics in conjunction with digital twins can improve their forecasting accuracy by 25%. As the logistics sector continues to evolve, the synergy between data analytics and digital twin technology is expected to drive further innovation and efficiency.

Enhanced Operational Efficiency

The Digital Twin In Logistic Market is experiencing a surge in demand due to the need for enhanced operational efficiency. Companies are increasingly adopting digital twin technology to create virtual replicas of their logistics operations, allowing for real-time monitoring and optimization. This technology enables organizations to simulate various scenarios, identify bottlenecks, and streamline processes. According to recent data, the implementation of digital twins can lead to a reduction in operational costs by up to 30%. As logistics companies strive to improve their service delivery and reduce lead times, the digital twin technology becomes a critical asset in achieving these goals.

Improved Supply Chain Visibility

In the Digital Twin In Logistic Market, improved supply chain visibility is a key driver of growth. Digital twin technology provides stakeholders with a comprehensive view of the entire supply chain, from raw material sourcing to final delivery. This visibility allows for better decision-making and enhances collaboration among various parties involved in the logistics process. Recent studies indicate that companies utilizing digital twins can achieve a 20% increase in supply chain transparency. As businesses seek to mitigate risks and respond swiftly to market changes, the adoption of digital twin technology is likely to become more prevalent.

Focus on Sustainability and Resource Optimization

Sustainability and resource optimization are becoming increasingly important in the Digital Twin In Logistic Market. Companies are under pressure to minimize their environmental impact while maximizing resource efficiency. Digital twin technology facilitates this by enabling organizations to simulate and analyze their logistics operations, identifying opportunities for reducing waste and energy consumption. Recent findings suggest that companies employing digital twins can achieve a 15% reduction in carbon emissions. As the logistics industry faces mounting scrutiny regarding its environmental footprint, the adoption of digital twin technology is expected to rise as a means of promoting sustainable practices.