Growing Environmental Regulations

The De-Agglomerating Equipment Market is also being shaped by growing environmental regulations. As industries face increasing scrutiny regarding their environmental impact, there is a pressing need for more sustainable manufacturing practices. De-agglomerating equipment that minimizes waste and energy consumption is becoming increasingly attractive. Companies are seeking solutions that not only enhance efficiency but also align with sustainability goals. The push for greener technologies is likely to drive innovation within the De-Agglomerating Equipment Market, as manufacturers develop equipment that meets both performance and environmental standards. This shift may result in a market growth rate of approximately 4% in the near future.

Increased Focus on Quality Control

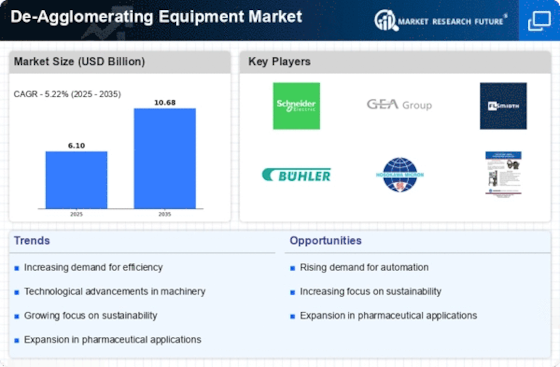

Quality control remains a pivotal driver for the De-Agglomerating Equipment Market. Industries such as chemicals, pharmaceuticals, and food processing are placing greater emphasis on maintaining product quality and consistency. The ability to achieve uniform particle sizes through effective de-agglomeration is critical for meeting regulatory standards and consumer expectations. As companies strive to enhance their quality assurance processes, investments in de-agglomerating technologies are likely to increase. This trend is supported by the fact that the quality control equipment market is projected to grow at a CAGR of 5% in the coming years, further propelling the De-Agglomerating Equipment Market.

Expansion of Food Processing Industry

The De-Agglomerating Equipment Market is significantly influenced by the expansion of the food processing industry. As consumer preferences shift towards processed and convenience foods, manufacturers are compelled to adopt advanced technologies to ensure product quality and consistency. De-agglomerating equipment plays a crucial role in achieving uniform particle sizes, which is essential for product texture and stability. The food processing sector is anticipated to witness a growth rate of around 4.5% annually, which may lead to increased demand for de-agglomerating solutions. This trend suggests a robust opportunity for the De-Agglomerating Equipment Market to cater to evolving industry needs.

Rising Demand in Pharmaceutical Sector

The De-Agglomerating Equipment Market is experiencing a notable surge in demand, particularly from the pharmaceutical sector. This industry requires precise particle size distribution for effective drug formulation and delivery. As pharmaceutical companies increasingly focus on enhancing bioavailability and solubility of active ingredients, the need for advanced de-agglomerating equipment becomes paramount. Recent data indicates that the pharmaceutical market is projected to grow at a compound annual growth rate (CAGR) of approximately 5.8% over the next five years. This growth is likely to drive investments in de-agglomerating technologies, thereby bolstering the De-Agglomerating Equipment Market.

Technological Innovations in Material Science

Technological innovations in material science are reshaping the De-Agglomerating Equipment Market. The development of new materials, particularly nanomaterials and advanced composites, necessitates precise particle size control to optimize performance. As industries such as electronics and aerospace increasingly utilize these materials, the demand for sophisticated de-agglomerating equipment is likely to rise. Recent advancements in de-agglomeration technologies, including high-energy milling and ultrasonic dispersion, are enhancing efficiency and effectiveness. This evolution in material processing could potentially lead to a market growth rate of 6% over the next few years, indicating a promising trajectory for the De-Agglomerating Equipment Market.