Rising Demand in Energy Sector

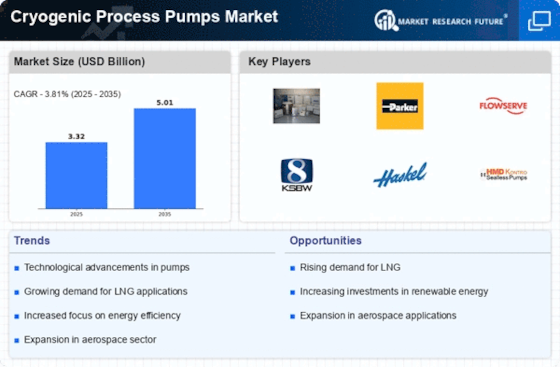

The Cryogenic Process Pumps Market is experiencing a notable surge in demand, particularly within the energy sector. As industries increasingly turn to liquefied natural gas (LNG) and other cryogenic fluids for energy production, the need for efficient and reliable pumping solutions becomes paramount. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 5.2% over the next few years, driven by the expansion of LNG infrastructure and the rising adoption of cryogenic technologies. This trend indicates a robust opportunity for manufacturers and suppliers within the Cryogenic Process Pumps Market to innovate and enhance their product offerings, ensuring they meet the evolving needs of energy producers.

Growth in Aerospace Applications

The aerospace sector is a significant driver for the Cryogenic Process Pumps Market, as the demand for cryogenic propellants continues to rise. With the increasing number of space exploration missions and advancements in satellite technology, the need for efficient cryogenic pumps is becoming more pronounced. The market for cryogenic pumps in aerospace applications is expected to witness a growth rate of around 6% annually, reflecting the industry's commitment to enhancing propulsion systems. This growth presents opportunities for companies to develop specialized pumps that cater to the unique requirements of aerospace applications, thereby solidifying their position in the Cryogenic Process Pumps Market.

Expansion of Industrial Applications

The expansion of industrial applications is a key driver for the Cryogenic Process Pumps Market. Industries such as chemical processing, metallurgy, and healthcare are increasingly utilizing cryogenic processes for various applications, including material handling and storage. The versatility of cryogenic pumps allows them to cater to a wide range of industrial needs, which is likely to propel market growth. With an anticipated CAGR of around 5.5%, the Cryogenic Process Pumps Market is set to benefit from the increasing adoption of cryogenic technologies across diverse sectors. This expansion presents opportunities for manufacturers to diversify their product lines and enhance their market presence.

Advancements in Cryogenic Technologies

Technological advancements play a crucial role in shaping the Cryogenic Process Pumps Market. Innovations in materials and design are leading to the development of more efficient and durable pumps. For instance, the introduction of advanced insulation materials and improved sealing technologies enhances the performance and reliability of cryogenic pumps. As industries seek to optimize their operations and reduce energy consumption, the demand for these advanced pumping solutions is likely to increase. The market is expected to benefit from these advancements, with a projected growth rate of 4.8% in the coming years, as companies strive to adopt cutting-edge technologies in the Cryogenic Process Pumps Market.

Increasing Focus on Environmental Sustainability

The Cryogenic Process Pumps Market is witnessing a shift towards environmentally sustainable practices. As industries become more aware of their carbon footprints, there is a growing emphasis on using cryogenic technologies that minimize environmental impact. This trend is particularly evident in sectors such as food processing and pharmaceuticals, where cryogenic processes are employed for preservation and storage. The market is likely to see a rise in demand for eco-friendly cryogenic pumps, which align with sustainability goals. This focus on environmental responsibility could drive a market growth rate of approximately 5% as companies seek to enhance their sustainability profiles within the Cryogenic Process Pumps Market.