Growing Energy Sector

The energy sector, particularly oil and gas, is a significant driver for the corrosion and scale inhibitor market. As exploration and production activities intensify, the need for effective inhibitors to combat corrosion in pipelines and equipment becomes critical. In 2025, the energy sector is anticipated to account for a considerable share of the market, with estimates indicating that it could represent over 40% of total demand. This trend is likely to continue as companies seek to enhance operational efficiency and minimize downtime caused by corrosion-related failures.

Stringent Regulatory Standards

The implementation of stringent environmental regulations regarding water quality and emissions is likely to propel the corrosion and scale inhibitor market. Governments are increasingly mandating the use of eco-friendly and non-toxic chemicals in industrial processes. This shift not only aims to protect the environment but also to ensure the safety of workers. As a result, manufacturers are compelled to innovate and develop formulations that comply with these regulations. The market for corrosion and scale inhibitors is expected to expand as industries adapt to these requirements, with a projected increase in demand for compliant products.

Rising Infrastructure Development

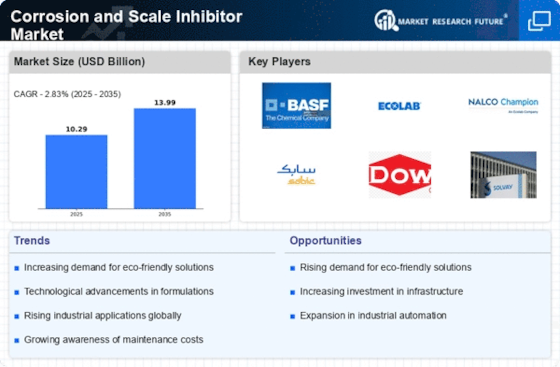

The ongoing expansion of infrastructure projects across various sectors, including construction, oil and gas, and water treatment, appears to drive the demand for corrosion and scale inhibitors. As new facilities are built and existing ones are upgraded, the need for effective protection against corrosion and scale buildup becomes paramount. In 2025, the corrosion and scale inhibitor market is projected to witness a substantial increase, with estimates suggesting a growth rate of approximately 5% annually. This growth is likely fueled by the increasing investments in infrastructure, which necessitate the use of inhibitors to prolong the lifespan of equipment and reduce maintenance costs.

Increased Awareness of Maintenance Costs

There is a growing recognition among industries of the financial implications associated with corrosion and scale buildup. The corrosion and scale inhibitor market is likely to benefit from this heightened awareness, as companies seek to mitigate maintenance costs and extend the lifespan of their assets. By investing in effective inhibitors, organizations can reduce downtime and avoid costly repairs. This trend is particularly evident in sectors such as manufacturing and utilities, where the cost of corrosion can be substantial. As a result, the market is expected to experience steady growth as more companies prioritize preventive measures.

Technological Innovations in Inhibitor Formulations

Advancements in chemical formulations and application technologies are transforming the corrosion and scale inhibitor market. Innovations such as nanotechnology and bio-based inhibitors are emerging, offering enhanced performance and reduced environmental impact. These developments not only improve the efficacy of inhibitors but also cater to the growing demand for sustainable solutions. As industries increasingly prioritize eco-friendly options, the market is expected to see a shift towards these advanced formulations, potentially leading to a market growth rate of 6% in the coming years.