Sustainability Initiatives in Continuous Annealing Line Market

Sustainability initiatives are becoming a pivotal driver in the Continuous Annealing Line Market. Manufacturers are increasingly focusing on reducing their carbon footprint and energy consumption. The integration of energy-efficient technologies and the use of renewable energy sources are gaining traction. For example, companies are investing in systems that utilize waste heat recovery, which can significantly lower energy costs. This shift towards sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers. As a result, the market is likely to see a rise in demand for eco-friendly continuous annealing lines, potentially leading to a market growth rate of around 4.8% in the coming years.

Technological Advancements in Continuous Annealing Line Market

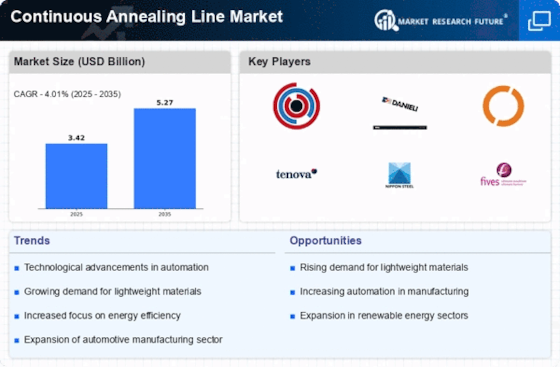

The Continuous Annealing Line Market is experiencing a surge in technological advancements that enhance production efficiency and product quality. Innovations such as automation, real-time monitoring, and advanced control systems are being integrated into annealing lines. These technologies not only reduce operational costs but also improve the consistency of the final product. For instance, the implementation of Industry 4.0 principles allows for better data analytics and predictive maintenance, which can lead to a reduction in downtime. As manufacturers increasingly adopt these technologies, the market is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years, indicating a robust demand for advanced continuous annealing solutions.

Rising Demand for High-Quality Steel in Continuous Annealing Line Market

The demand for high-quality steel is a significant driver in the Continuous Annealing Line Market. As industries such as automotive, construction, and appliances require materials that meet stringent quality standards, the need for advanced annealing processes becomes critical. Continuous annealing lines are essential for producing high-strength, low-alloy steels that exhibit superior mechanical properties. This trend is particularly evident in the automotive sector, where manufacturers are increasingly utilizing advanced high-strength steels to enhance vehicle safety and performance. Consequently, the market is expected to grow steadily, with projections indicating an increase in demand for continuous annealing lines by approximately 5.5% over the next few years.

Market Expansion in Emerging Economies for Continuous Annealing Line Market

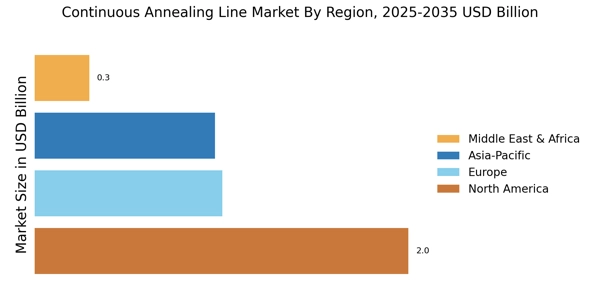

The Continuous Annealing Line Market is witnessing notable expansion in emerging economies, driven by rapid industrialization and urbanization. Countries in Asia-Pacific and Latin America are investing heavily in their manufacturing sectors, which is creating a substantial demand for advanced annealing technologies. The increasing production of automotive and consumer goods in these regions necessitates efficient processing solutions, thereby propelling the market forward. Furthermore, government initiatives aimed at boosting local manufacturing capabilities are likely to enhance the adoption of continuous annealing lines. This trend suggests a potential market growth of approximately 6% in these regions over the next few years, reflecting the growing importance of continuous annealing in modern manufacturing.

Increased Investment in Manufacturing Infrastructure for Continuous Annealing Line Market

Increased investment in manufacturing infrastructure is a key driver for the Continuous Annealing Line Market. Governments and private sectors are channeling funds into modernizing production facilities to enhance efficiency and competitiveness. This investment is particularly evident in regions where manufacturing is a cornerstone of economic growth. The establishment of new plants and the upgrading of existing facilities to incorporate continuous annealing lines are becoming commonplace. Such developments not only improve production capabilities but also align with global trends towards automation and smart manufacturing. As a result, the market is likely to experience a growth trajectory of around 5% in the coming years, reflecting the ongoing commitment to enhancing manufacturing processes.