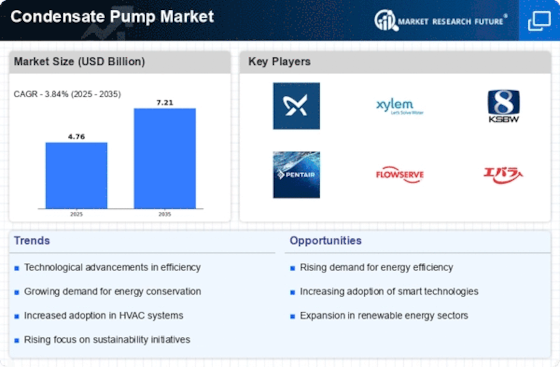

Rising Demand in HVAC Systems

The increasing demand for heating, ventilation, and air conditioning (HVAC) systems is a primary driver for the Condensate Pump Market. As urbanization accelerates, the need for efficient climate control systems in residential and commercial buildings has surged. According to recent data, the HVAC market is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. This growth directly correlates with the rising need for condensate pumps, which are essential for removing condensate water from HVAC systems. The integration of advanced technologies in HVAC systems further enhances the efficiency of condensate pumps, thereby driving their adoption in the market. Consequently, manufacturers are focusing on developing high-performance condensate pumps to meet the evolving demands of the HVAC sector.

Industrial Growth and Expansion

The expansion of various industries, including manufacturing, pharmaceuticals, and food processing, is significantly influencing the Condensate Pump Market. As industries grow, the need for efficient condensate management systems becomes increasingly critical. For instance, the manufacturing sector has witnessed a resurgence, with many companies investing in new facilities and upgrading existing ones. This trend is expected to boost the demand for condensate pumps, as they play a vital role in maintaining operational efficiency and preventing water damage. Market analysis indicates that the industrial sector's growth could lead to a substantial increase in the demand for condensate pumps, with projections suggesting a potential market size increase of over 10% in the coming years. This industrial expansion underscores the importance of reliable condensate pump solutions.

Regulatory Compliance and Standards

The implementation of stringent regulations regarding water management and waste disposal is a significant driver for the Condensate Pump Market. Governments and regulatory bodies are increasingly mandating industries to adopt efficient water management practices to minimize environmental impact. This regulatory landscape compels industries to invest in condensate pumps that comply with these standards. For example, regulations aimed at reducing water waste and improving energy efficiency are pushing companies to upgrade their condensate management systems. As a result, the demand for high-quality, compliant condensate pumps is expected to rise. Market data suggests that adherence to these regulations could lead to a market growth rate of approximately 7% annually, as industries seek to avoid penalties and enhance their sustainability profiles.

Increased Focus on Energy Efficiency

The heightened focus on energy efficiency across various sectors is a crucial driver for the Condensate Pump Market. As energy costs continue to rise, industries are seeking solutions that not only reduce operational expenses but also minimize their carbon footprint. Condensate pumps that are designed for energy efficiency are becoming increasingly popular, as they contribute to overall system performance and sustainability. Market analysis reveals that energy-efficient condensate pumps can lead to energy savings of up to 30%, making them an attractive option for businesses aiming to optimize their operations. This trend is likely to propel the demand for such pumps, with projections indicating a potential market growth of around 9% in the coming years. The emphasis on energy efficiency is thus reshaping purchasing decisions within the condensate pump market.

Technological Innovations in Pump Design

Technological advancements in pump design and materials are driving the evolution of the Condensate Pump Market. Innovations such as the development of energy-efficient pumps and smart monitoring systems are enhancing the performance and reliability of condensate pumps. These advancements not only improve operational efficiency but also reduce energy consumption, aligning with the growing emphasis on sustainability. For instance, the introduction of variable speed drives and advanced control systems allows for better management of condensate flow, which is crucial in various applications. Market trends indicate that the adoption of these innovative technologies could lead to a significant increase in the market share of advanced condensate pumps, potentially reaching a growth rate of 8% over the next few years. This technological shift is reshaping the competitive landscape of the condensate pump industry.