Advancements in Technology

Technological advancements play a pivotal role in shaping the Computer Aided Manufacturing Market. Innovations in software and hardware are continuously enhancing the capabilities of computer-aided manufacturing systems. For instance, the introduction of advanced simulation tools and real-time data analytics is enabling manufacturers to optimize their production processes. Recent statistics indicate that the adoption of advanced manufacturing technologies could lead to a productivity increase of up to 30% in certain sectors. Furthermore, the integration of Internet of Things (IoT) devices is facilitating better connectivity and data exchange between machines, which enhances operational efficiency. As technology continues to evolve, the Computer Aided Manufacturing Market is poised for substantial growth, driven by the need for more sophisticated and efficient manufacturing solutions.

Rising Demand for Automation

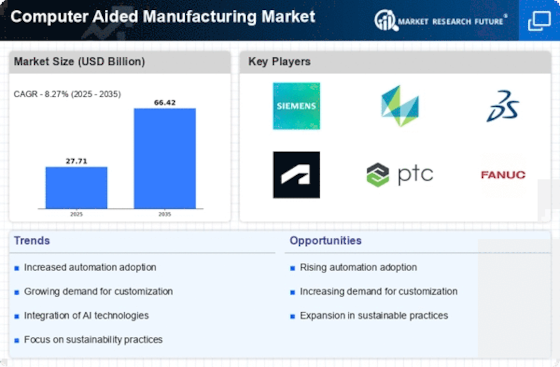

The Computer Aided Manufacturing Market is experiencing a notable surge in demand for automation across various sectors. Industries are increasingly adopting automated solutions to enhance productivity and reduce operational costs. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 9% over the next five years. This trend is driven by the need for precision and efficiency in manufacturing processes, which computer-aided manufacturing systems can provide. As companies strive to remain competitive, the integration of automated systems into manufacturing workflows is becoming essential. This shift not only streamlines operations but also minimizes human error, thereby improving overall product quality. Consequently, the Computer Aided Manufacturing Market is likely to benefit significantly from this growing inclination towards automation.

Growing Focus on Customization

The Computer Aided Manufacturing Market is witnessing a growing focus on customization, as consumers increasingly demand tailored products. This trend is particularly evident in industries such as automotive and consumer electronics, where personalized features are becoming a key selling point. Manufacturers are leveraging computer-aided manufacturing systems to produce customized products efficiently, allowing for shorter lead times and reduced costs. Data suggests that the market for customized manufacturing solutions is expected to expand significantly, with a projected growth rate of around 12% annually. This shift towards customization not only enhances customer satisfaction but also drives innovation within the Computer Aided Manufacturing Market, as companies seek to differentiate themselves in a competitive landscape.

Regulatory Compliance and Quality Standards

The Computer Aided Manufacturing Market is increasingly influenced by regulatory compliance and quality standards. As industries face stricter regulations regarding product quality and safety, manufacturers are compelled to adopt computer-aided manufacturing systems that ensure compliance. These systems facilitate precise documentation and traceability, which are essential for meeting regulatory requirements. Data indicates that companies that implement robust quality management systems can reduce defects by up to 50%. This emphasis on compliance not only enhances product quality but also mitigates risks associated with non-compliance. Consequently, the Computer Aided Manufacturing Market is likely to experience growth as manufacturers seek solutions that align with regulatory standards and improve overall operational efficiency.

Increased Investment in Research and Development

Investment in research and development is a critical driver for the Computer Aided Manufacturing Market. Companies are allocating substantial resources to innovate and improve their manufacturing processes. This focus on R&D is essential for developing new technologies that enhance efficiency and reduce costs. Recent reports indicate that R&D spending in the manufacturing sector has increased by approximately 15% over the past few years. This investment is aimed at exploring new materials, advanced manufacturing techniques, and automation solutions. As manufacturers strive to stay ahead of the curve, the Computer Aided Manufacturing Market is likely to see a surge in innovative products and solutions that cater to evolving market demands.