Regulatory Compliance and Standards

The Cold Phosphating Chemical Market is significantly impacted by regulatory compliance and industry standards aimed at ensuring product safety and environmental protection. Governments and regulatory bodies are increasingly implementing stringent guidelines regarding the use of chemicals in manufacturing processes. This has led to a growing demand for phosphating chemicals that comply with these regulations, as companies seek to avoid penalties and maintain their market reputation. Market analysis suggests that adherence to these standards can enhance product credibility and open new market opportunities. As a result, manufacturers are compelled to invest in compliant formulations and processes, which may drive innovation and improve the overall quality of products in the cold phosphating chemical market. This focus on regulatory compliance is likely to shape the future landscape of the industry.

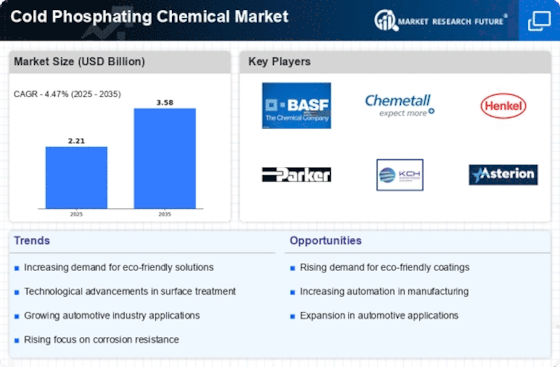

Rising Demand for Eco-Friendly Coatings

The Cold Phosphating Chemical Market is experiencing a notable shift towards eco-friendly coatings, driven by increasing environmental regulations and consumer preferences for sustainable products. As industries seek to reduce their carbon footprint, the demand for phosphating chemicals that are less harmful to the environment is on the rise. This trend is reflected in the growing adoption of cold phosphating processes, which utilize less energy and produce fewer emissions compared to traditional methods. Market data indicates that the eco-friendly segment is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years, highlighting the industry's commitment to sustainability. Consequently, manufacturers are investing in research and development to create innovative phosphating solutions that align with these environmental goals.

Increasing Focus on Corrosion Protection

The Cold Phosphating Chemical Market is witnessing a heightened focus on corrosion protection across various sectors, including construction, manufacturing, and marine applications. Corrosion poses a significant challenge to the longevity and performance of metal components, leading to increased maintenance costs and safety concerns. As industries recognize the importance of effective corrosion management, the demand for cold phosphating chemicals is expected to surge. Recent studies indicate that The Cold Phosphating Chemical Market is projected to reach USD 30 billion by 2027, with phosphating chemicals playing a pivotal role in this growth. This trend underscores the necessity for manufacturers to develop advanced phosphating solutions that provide superior corrosion resistance, thereby enhancing the overall value proposition of their products in the cold phosphating chemical market.

Expansion of Automotive and Aerospace Industries

The Cold Phosphating Chemical Market is significantly influenced by the expansion of the automotive and aerospace sectors. These industries require high-performance coatings to enhance corrosion resistance and improve the durability of components. As production levels in automotive manufacturing increase, the demand for cold phosphating chemicals is expected to rise correspondingly. Recent market analysis suggests that the automotive sector alone accounts for nearly 40% of the total demand for phosphating chemicals, with a projected growth rate of 5% annually. Additionally, the aerospace industry is also witnessing a resurgence, further driving the need for advanced phosphating solutions. This expansion presents a lucrative opportunity for manufacturers to cater to the specific needs of these industries, thereby bolstering the overall growth of the cold phosphating chemical market.

Technological Innovations in Phosphating Processes

Technological advancements play a crucial role in shaping the Cold Phosphating Chemical Market. Innovations in phosphating processes, such as the development of new formulations and application techniques, are enhancing the efficiency and effectiveness of cold phosphating. These advancements not only improve the quality of the coatings but also reduce production costs and environmental impact. For instance, the introduction of automated phosphating systems has streamlined operations, allowing for higher throughput and consistency in coating applications. Market data indicates that companies investing in these technologies are likely to see a competitive edge, as they can offer superior products that meet the evolving demands of various industries. As a result, the market is expected to witness a steady growth trajectory, driven by these technological innovations.