Market Analysis

In-depth Analysis of CNC Controller Market Industry Landscape

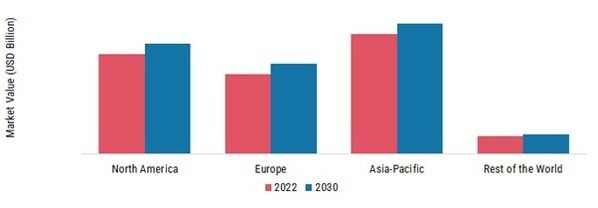

The market elements of the CNC regulator market mirror a dynamic and developing scene driven by innovative progressions and industry requests. CNC regulators assume an essential part in robotizing machine devices, empowering accuracy, and productivity in assembling processes. One of the key drivers forming the market is the rising reception of CNC machines across different ventures like aviation, car, and medical services. The interest for high-accuracy machining and the need to improve efficiency are impelling the development of the CNC regulator market. The improvement of cutting edge CNC regulators with highlights like continuous observing, versatile control, and combination with Industry 4.0 advances are building up momentum. Makers are looking for regulators that deal further developed UIs, quicker handling speeds, and more prominent adaptability to adjust to different machining applications. The market is seeing a shift towards smart and connected CNC frameworks that work with information driven navigation and improve generally functional effectiveness. Worldwide monetary models and modern ventures likewise add to the market elements of CNC regulators. As economies recuperate from monetary slumps, ventures put resources into modernizing their assembling offices to remain important. The interest for CNC regulators is intently attached to capital consumption in ventures, making it basic for market players to comprehend and adjust to monetary cycles. Consistence with industry principles and guidelines is fundamental for makers to guarantee the wellbeing, unwavering quality, and interoperability of CNC frameworks. Changes in guidelines, particularly those connected with ecological manageability and working environment security, can affect the plan and usefulness of CNC regulators, provoking producers to adjust to developing prerequisites. Manufacturers are progressively centered around creating energy-proficient CNC regulators to line up with worldwide supportability objectives. End-clients are showing an inclination for eco-accommodating arrangements, prompting developments in power the executives and the joining of energy-effective parts in CNC regulators. Topographically, market elements differ considering local modern patterns and monetary circumstances. Creating economies with a blossoming producing area are seeing expanded interest for CNC regulators as ventures put resources into current innovation. Conversely, mature markets are driven by the supplanting of obsolete frameworks with cutting edge CNC regulators that proposition improved abilities.

Leave a Comment