North America : Market Leader in Services

North America is poised to maintain its leadership in the Chemical Pump Repair and Maintenance Services Market, holding a market size of $1.55B in 2025. The region's growth is driven by stringent regulatory frameworks, increasing industrial activities, and a rising demand for efficient pump systems. The focus on sustainability and energy efficiency further propels the market, as companies seek to optimize operations and reduce environmental impact.

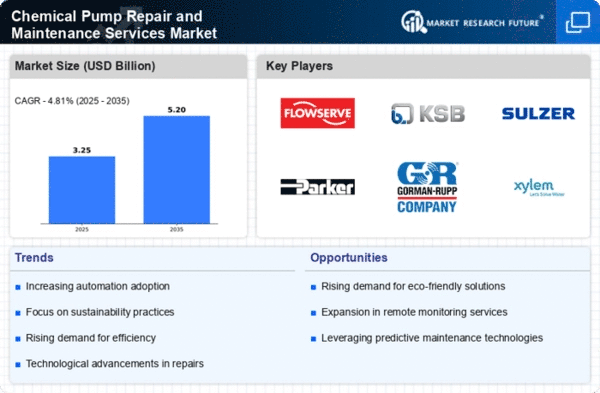

The competitive landscape is robust, with key players like Flowserve Corporation, Parker Hannifin Corporation, and Xylem Inc. leading the charge. The U.S. is the primary market, supported by advanced infrastructure and technological innovations. The presence of established companies ensures a steady supply of high-quality services, catering to various sectors including oil & gas, chemicals, and water treatment.

Europe : Emerging Market Dynamics

Europe's Chemical Pump Repair and Maintenance Services Market is projected to reach $0.95B by 2025, driven by increasing investments in industrial automation and stringent environmental regulations. The demand for reliable and efficient pump systems is rising, particularly in the chemical and pharmaceutical sectors. Regulatory initiatives aimed at reducing emissions and enhancing operational efficiency are key growth catalysts in this region.

Germany and the UK are leading markets, with companies like KSB SE & Co. KGaA and Sulzer Ltd playing pivotal roles. The competitive landscape is characterized by a mix of established players and innovative startups, fostering a dynamic environment. The European market is increasingly focused on sustainability, with many firms investing in eco-friendly technologies and practices.

Asia-Pacific : Rapid Growth and Innovation

The Asia-Pacific region is witnessing significant growth in the Chemical Pump Repair and Maintenance Services Market, projected to reach $0.85B by 2025. This growth is fueled by rapid industrialization, urbanization, and increasing demand for energy-efficient solutions. Countries like China and India are at the forefront, with government initiatives promoting infrastructure development and modernization of industrial facilities.

The competitive landscape is evolving, with both local and international players vying for market share. Companies such as Ebara Corporation and Weir Group PLC are expanding their presence, leveraging technological advancements to offer innovative solutions. The region's focus on sustainability and regulatory compliance is driving demand for high-quality repair and maintenance services, ensuring long-term growth prospects.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region, though smaller in size at $0.15B, presents emerging opportunities in the Chemical Pump Repair and Maintenance Services Market. The growth is driven by increasing investments in oil & gas and chemical industries, alongside a rising focus on infrastructure development. Regulatory frameworks are gradually evolving, promoting better maintenance practices and operational efficiency in industrial sectors.

Countries like the UAE and South Africa are leading the market, with a growing number of local and international players entering the space. The competitive landscape is characterized by partnerships and collaborations aimed at enhancing service offerings. As the region continues to develop, the demand for reliable pump services is expected to rise, creating a favorable environment for growth.