North America : Market Leader in Services

North America is poised to maintain its leadership in the Chemical Mixing Equipment Maintenance and Repair Services Market, holding a market size of $1.25B in 2025. Key growth drivers include the increasing demand for efficient manufacturing processes and stringent regulatory standards that necessitate regular maintenance. The region's advanced technological infrastructure and investment in R&D further bolster market expansion, ensuring compliance with safety and environmental regulations.

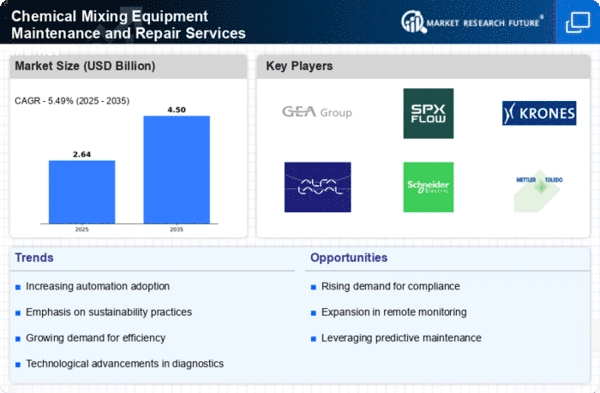

The competitive landscape is characterized by major players such as GEA Group, SPX Flow, and Emerson Electric, which dominate the market with innovative solutions. The U.S. leads the charge, supported by a robust industrial base and a focus on automation and digitalization. This environment fosters collaboration among key stakeholders, enhancing service delivery and customer satisfaction, thereby solidifying North America's market position.

Europe : Regulatory-Driven Market Growth

Europe's Chemical Mixing Equipment Maintenance and Repair Services Market is projected to reach $0.75B by 2025, driven by stringent regulations and a growing emphasis on sustainability. The European Union's commitment to environmental standards and safety regulations compels industries to prioritize maintenance services, ensuring compliance and operational efficiency. This regulatory landscape fosters innovation and investment in advanced maintenance technologies, enhancing service quality across sectors.

Leading countries such as Germany, France, and the UK are at the forefront of this market, with key players like Krones AG and Alfa Laval driving competitive dynamics. The presence of established manufacturers and a focus on eco-friendly practices create a conducive environment for market growth. As industries adapt to evolving regulations, the demand for specialized maintenance services is expected to rise, further solidifying Europe's market position.

Asia-Pacific : Emerging Market Potential

The Asia-Pacific region is witnessing significant growth in the Chemical Mixing Equipment Maintenance and Repair Services Market, projected to reach $0.4B by 2025. This growth is fueled by rapid industrialization, increasing manufacturing activities, and a rising focus on quality assurance. Countries like China and India are investing heavily in infrastructure and technology, driving demand for efficient maintenance services to enhance productivity and reduce downtime.

The competitive landscape is evolving, with both local and international players vying for market share. Companies such as Honeywell International and Parker Hannifin are expanding their presence in the region, leveraging technological advancements to offer innovative solutions. As the market matures, the emphasis on service quality and reliability will become paramount, positioning Asia-Pacific as a key player in the global market.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region represents an emerging frontier in the Chemical Mixing Equipment Maintenance and Repair Services Market, with a projected size of $0.1B by 2025. The region's growth is driven by increasing industrial activities, particularly in oil and gas, and a growing awareness of the importance of equipment maintenance. As industries expand, the demand for reliable maintenance services is expected to rise, presenting significant opportunities for service providers.

Countries like the UAE and South Africa are leading the charge, with investments in infrastructure and technology enhancing service delivery. The competitive landscape is still developing, with opportunities for both local and international players to establish a foothold. As the market evolves, the focus will shift towards quality and efficiency, positioning the region for future growth in the maintenance services sector.