North America : Market Leader in Services

North America is poised to maintain its leadership in the Chemical Plant Maintenance and Repair Services Market, holding a significant market share of 22.25% as of 2024. The region's growth is driven by stringent regulatory frameworks, increasing investments in infrastructure, and a rising demand for efficient maintenance solutions. The focus on sustainability and technological advancements further propels market expansion, making it a hub for innovation in chemical processing.

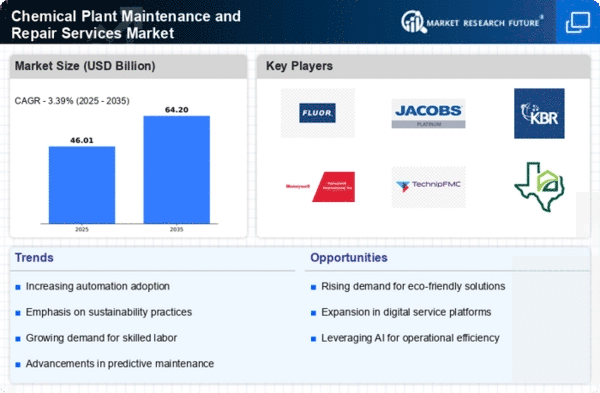

The United States stands out as the leading country in this sector, hosting major players like Fluor Corporation, Jacobs Engineering Group, and Honeywell International Inc. The competitive landscape is characterized by a mix of established firms and emerging players, all vying for market share. The presence of advanced technologies and skilled labor enhances the region's capability to deliver high-quality maintenance services, ensuring operational efficiency and safety in chemical plants.

Europe : Growing Demand and Innovation

Europe's Chemical Plant Maintenance and Repair Services Market is witnessing robust growth, with a market size of €12.5 billion. The region benefits from a strong regulatory environment that emphasizes safety and environmental standards, driving demand for maintenance services. Additionally, the push for digital transformation and automation in chemical plants is creating new opportunities for service providers, enhancing operational efficiency and reducing downtime.

Leading countries such as Germany, France, and the UK are at the forefront of this market, supported by key players like TechnipFMC and Babcock International Group. The competitive landscape is marked by innovation and collaboration among firms to meet the evolving needs of the industry. As companies invest in advanced technologies, the region is set to strengthen its position in the global market, ensuring sustainable growth and improved service delivery.

Asia-Pacific : Rapid Growth and Opportunities

The Asia-Pacific region is emerging as a significant player in the Chemical Plant Maintenance and Repair Services Market, with a market size of $8.0 billion. The growth is fueled by increasing industrialization, urbanization, and a rising focus on safety and compliance with international standards. Governments are implementing policies to enhance the operational efficiency of chemical plants, which is further driving the demand for maintenance services across the region.

Countries like China, India, and Japan are leading the charge, with a growing number of local and international players entering the market. The competitive landscape is evolving, with companies investing in innovative solutions to cater to the diverse needs of the chemical industry. As the region continues to develop, the demand for specialized maintenance services is expected to rise, presenting lucrative opportunities for service providers.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region, with a market size of $2.75 billion, is gradually emerging in the Chemical Plant Maintenance and Repair Services Market. The growth is driven by increasing investments in the chemical sector, particularly in countries like Saudi Arabia and the UAE, where there is a strong focus on diversifying economies and enhancing industrial capabilities. Regulatory frameworks are evolving to support safety and environmental standards, which is crucial for market expansion.

Key players in this region are beginning to establish a foothold, with companies like Aker Solutions ASA gaining traction. The competitive landscape is characterized by a mix of local and international firms, all aiming to capitalize on the growing demand for maintenance services. As the region continues to develop its chemical industry, the need for specialized maintenance solutions will likely increase, paving the way for future growth.