Sustainability Focus

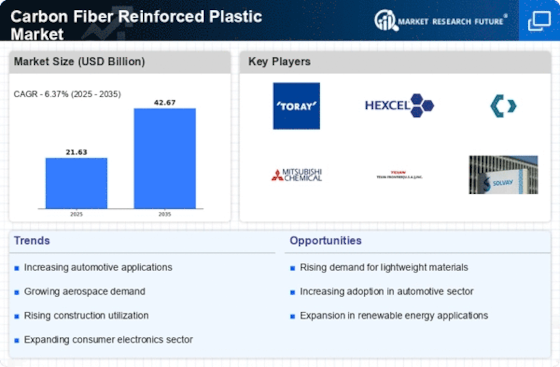

The increasing emphasis on sustainability is a pivotal driver for the Carbon Fiber Reinforced Plastic Market. As industries strive to reduce their carbon footprints, the demand for lightweight and durable materials has surged. Carbon fiber reinforced plastics offer a compelling solution due to their recyclability and lower energy consumption during production compared to traditional materials. This shift towards eco-friendly alternatives is evident in sectors such as automotive and aerospace, where manufacturers are actively seeking materials that align with their sustainability goals. The market is projected to witness a compound annual growth rate (CAGR) of approximately 10% over the next five years, driven by this growing focus on sustainable practices.

Aerospace Industry Demand

The aerospace industry remains a dominant force driving the Carbon Fiber Reinforced Plastic Market. With the ongoing pursuit of fuel efficiency and performance enhancements, aerospace manufacturers are increasingly utilizing carbon fiber reinforced plastics in aircraft structures and components. The lightweight nature of these materials contributes to significant weight savings, which directly translates to reduced fuel consumption and lower operational costs. Recent data suggests that carbon fiber composites could constitute up to 50% of the structural weight of new aircraft models by 2030. This trend not only bolsters the market but also highlights the material's essential role in meeting stringent regulatory requirements for emissions and efficiency.

Technological Advancements

Technological advancements play a crucial role in propelling the Carbon Fiber Reinforced Plastic Market forward. Innovations in manufacturing processes, such as automated fiber placement and advanced resin systems, have enhanced the efficiency and cost-effectiveness of carbon fiber production. These advancements not only improve the mechanical properties of the materials but also expand their applications across various sectors. For instance, the aerospace industry is increasingly adopting carbon fiber reinforced plastics for structural components, leading to weight reductions and improved fuel efficiency. As technology continues to evolve, the market is expected to grow significantly, with estimates suggesting a market size reaching USD 30 billion by 2028.

Consumer Electronics Growth

The burgeoning consumer electronics sector is emerging as a noteworthy driver for the Carbon Fiber Reinforced Plastic Market. As manufacturers seek to create lightweight, durable, and aesthetically appealing products, carbon fiber reinforced plastics are increasingly being adopted in devices such as smartphones, laptops, and wearables. The material's unique properties allow for innovative designs while maintaining structural integrity. Market analysis indicates that the consumer electronics segment could witness a growth rate of around 8% annually, driven by the rising demand for high-performance devices. This trend not only enhances the market's diversity but also underscores the versatility of carbon fiber reinforced plastics across various applications.

Electric Vehicle Integration

The integration of carbon fiber reinforced plastics in electric vehicles (EVs) is emerging as a significant driver for the Carbon Fiber Reinforced Plastic Market. As the automotive sector shifts towards electrification, the need for lightweight materials that enhance battery efficiency and overall vehicle performance becomes paramount. Carbon fiber reinforced plastics provide an ideal solution, offering high strength-to-weight ratios that contribute to extended driving ranges. Major automotive manufacturers are increasingly incorporating these materials into their EV designs, which is likely to propel market growth. Projections indicate that the EV segment could account for over 25% of the carbon fiber reinforced plastics market by 2030, underscoring the material's critical role in the future of transportation.