Advancements in Sensor Technology

Technological advancements in sensor technology are playing a crucial role in shaping the Capacitive Ceramic Pressure Sensor Market. Innovations such as miniaturization, improved sensitivity, and enhanced signal processing capabilities are making capacitive ceramic pressure sensors more appealing to a wider range of applications. These advancements enable sensors to perform effectively in challenging environments, thereby expanding their usability in sectors like aerospace and medical devices. The market is expected to benefit from these technological improvements, with projections indicating a potential growth rate of 7% annually as manufacturers continue to innovate and meet the evolving needs of various industries.

Growing Focus on Safety Regulations

The Capacitive Ceramic Pressure Sensor Market is also being propelled by a growing focus on safety regulations across various sectors. Governments and regulatory bodies are implementing stringent safety standards that necessitate the use of reliable pressure measurement devices. Capacitive ceramic pressure sensors, known for their durability and accuracy, are increasingly being adopted to comply with these regulations. Industries such as oil and gas, chemical processing, and food and beverage are particularly affected, as they require precise pressure monitoring to ensure operational safety. This regulatory push is likely to result in a steady increase in demand for capacitive ceramic pressure sensors, further solidifying their market position.

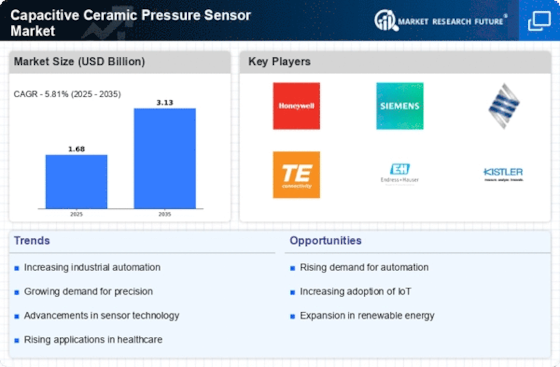

Rising Demand for Precision Measurement

The Capacitive Ceramic Pressure Sensor Market is experiencing a notable increase in demand for precision measurement devices across various sectors. Industries such as automotive, aerospace, and healthcare are increasingly relying on accurate pressure measurements to enhance safety and efficiency. The need for high-performance sensors that can withstand extreme conditions is driving innovation in sensor technology. As a result, manufacturers are focusing on developing capacitive ceramic pressure sensors that offer superior accuracy and reliability. This trend is expected to contribute to a compound annual growth rate (CAGR) of approximately 6% in the capacitive ceramic pressure sensor market over the next few years, indicating a robust growth trajectory.

Expansion of Automation in Manufacturing

The ongoing expansion of automation in manufacturing processes is significantly influencing the Capacitive Ceramic Pressure Sensor Market. As industries strive for increased efficiency and reduced operational costs, the integration of advanced sensor technologies becomes paramount. Capacitive ceramic pressure sensors are being utilized in automated systems for real-time monitoring and control of pressure levels. This integration not only enhances productivity but also minimizes the risk of equipment failure. The market is projected to witness a surge in demand for these sensors, with estimates suggesting a potential increase in market size by 20% over the next five years, driven by the automation trend.

Increasing Adoption in Renewable Energy Sector

The increasing adoption of capacitive ceramic pressure sensors in the renewable energy sector is emerging as a significant driver for the Capacitive Ceramic Pressure Sensor Market. As the world shifts towards sustainable energy solutions, the demand for efficient pressure monitoring in applications such as wind turbines and solar power systems is on the rise. Capacitive ceramic pressure sensors are favored for their reliability and performance in harsh environmental conditions, making them ideal for renewable energy applications. This trend is expected to contribute to a substantial increase in market demand, with estimates suggesting a growth potential of 15% in the renewable energy segment over the next few years.