Growth in Renewable Energy Sector

The growth of the renewable energy sector in Canada is emerging as a potential driver for the reciprocating compressor market. As the country invests in alternative energy sources, such as hydrogen and biogas, the need for efficient gas compression solutions becomes critical. Reciprocating compressors are well-suited for these applications due to their ability to handle varying gas compositions and pressures. The market could see an increase in demand as more renewable energy projects are initiated, potentially leading to a market valuation of $1.5 billion by 2030. This shift towards renewable energy may create new opportunities for manufacturers within the reciprocating compressor market.

Rising Demand in Oil and Gas Sector

The oil and gas sector in Canada is experiencing a notable resurgence, which appears to be driving the growth of the reciprocating compressor market. As exploration and production activities ramp up, the need for efficient and reliable compression solutions becomes paramount. In 2025, the sector is projected to contribute significantly to the overall market, with an estimated value of $2 billion. This demand is likely to be fueled by the increasing extraction of unconventional resources, necessitating advanced compressor technologies to handle varying pressures and flow rates. Consequently, manufacturers are focusing on developing high-performance reciprocating compressors tailored for this sector, thereby enhancing their market presence.

Technological Innovations in Design

Technological innovations in the design of reciprocating compressors are playing a crucial role in shaping the market landscape in Canada. Recent advancements, such as the integration of smart technologies and IoT capabilities, are enhancing operational efficiency and reliability. These innovations allow for real-time monitoring and predictive maintenance, which can significantly reduce downtime and operational costs. As industries increasingly seek to optimize their processes, the demand for technologically advanced compressors is expected to rise. This trend may lead to a more competitive environment within the reciprocating compressor market, as companies strive to offer cutting-edge solutions.

Expansion of Industrial Applications

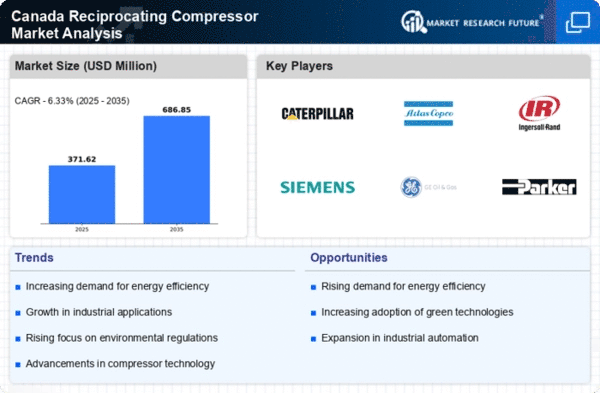

The reciprocating compressor market is witnessing an expansion in industrial applications across various sectors in Canada. Industries such as manufacturing, food processing, and pharmaceuticals are increasingly adopting these compressors for their operational needs. The market is expected to grow at a CAGR of 5.5% from 2025 to 2030, driven by the need for efficient gas compression in production processes. Furthermore, the versatility of reciprocating compressors allows them to be utilized in diverse applications, from refrigeration to pneumatic conveying. This adaptability is likely to attract more industries, thereby bolstering the market's growth trajectory.

Government Regulations and Standards

Government regulations in Canada are becoming increasingly stringent regarding emissions and energy efficiency, which may positively impact the reciprocating compressor market. Compliance with these regulations often necessitates the adoption of advanced compressor technologies that minimize environmental impact. As a result, manufacturers are investing in research and development to create compressors that meet these standards while maintaining high performance. The market could see a shift towards eco-friendly models, potentially increasing their market share. This regulatory landscape is likely to drive innovation and enhance the competitiveness of the reciprocating compressor market.