Investment in Energy Efficiency

Energy efficiency remains a critical focus for industries in Germany, significantly impacting the reciprocating compressor market. With rising energy costs and stringent regulations aimed at reducing carbon emissions, companies are increasingly investing in energy-efficient compressor systems. The market is witnessing a shift towards advanced reciprocating compressors that offer improved energy performance, potentially reducing operational costs by up to 20%. This trend aligns with Germany's commitment to sustainability and energy transition, as businesses seek to optimize their energy consumption. The emphasis on energy efficiency not only enhances the competitiveness of companies but also drives innovation within the reciprocating compressor market, fostering the development of next-generation technologies.

Growth of Renewable Energy Sector

The expansion of the renewable energy sector in Germany is poised to influence the reciprocating compressor market positively. As the country transitions towards greener energy sources, the demand for reliable and efficient compression solutions for biogas and hydrogen production is increasing. Reciprocating compressors play a vital role in these applications, ensuring the effective handling of gases produced from renewable sources. The market is expected to see a rise in investments, with projections indicating a potential increase in market size by 15% over the next five years. This growth reflects the broader trend of integrating renewable energy solutions into existing infrastructures, thereby enhancing the relevance of the reciprocating compressor market in the evolving energy landscape.

Rising Demand in Industrial Applications

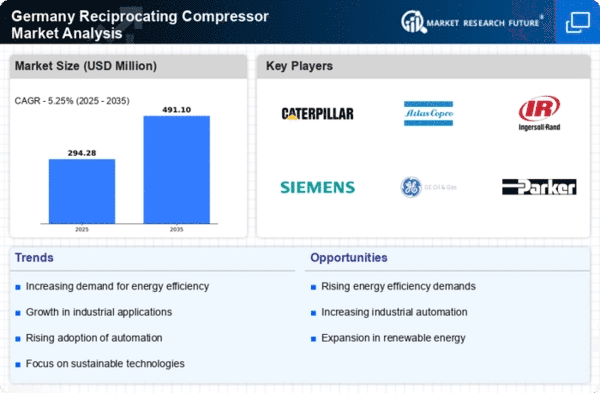

The reciprocating compressor market in Germany experiences a notable surge in demand due to the increasing industrial applications across various sectors. Industries such as manufacturing, oil and gas, and chemical processing are increasingly relying on reciprocating compressors for their efficiency and reliability. In 2025, the market is projected to grow at a CAGR of approximately 4.5%, driven by the need for compressed air and gas in production processes. This growth is further supported by the expansion of manufacturing facilities and the modernization of existing plants, which necessitate the integration of advanced compressor technologies. As industries strive for operational efficiency, the reciprocating compressor market is likely to benefit from this trend, indicating a robust future for manufacturers and suppliers in the sector.

Technological Innovations in Compressor Design

Technological innovations are reshaping the landscape of the reciprocating compressor market in Germany. Manufacturers are increasingly focusing on developing advanced compressor designs that enhance performance, reliability, and maintenance. Innovations such as variable speed drives and advanced control systems are becoming more prevalent, allowing for better energy management and operational flexibility. These advancements not only improve the efficiency of compressors but also extend their lifespan, reducing the total cost of ownership for users. As companies seek to leverage these technologies, the reciprocating compressor market is likely to witness a shift towards more sophisticated and intelligent systems, catering to the evolving needs of various industries.

Increasing Focus on Maintenance and Service Solutions

The reciprocating compressor market in Germany is experiencing a growing emphasis on maintenance and service solutions. As industries recognize the importance of minimizing downtime and ensuring optimal performance, there is a rising demand for comprehensive service packages that include regular maintenance, monitoring, and support. This trend is particularly relevant in sectors where reliability is paramount, such as pharmaceuticals and food processing. Companies are increasingly investing in predictive maintenance technologies that utilize data analytics to anticipate failures before they occur. This proactive approach not only enhances operational efficiency but also drives growth in the service segment of the reciprocating compressor market, indicating a shift towards a more service-oriented business model.