Rising Demand in Oil and Gas Sector

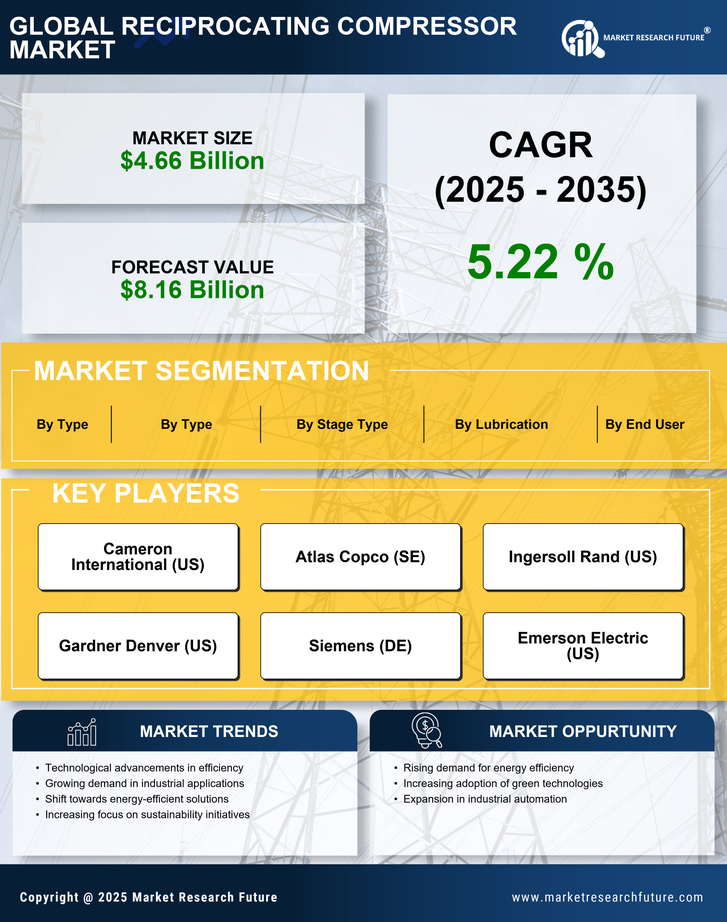

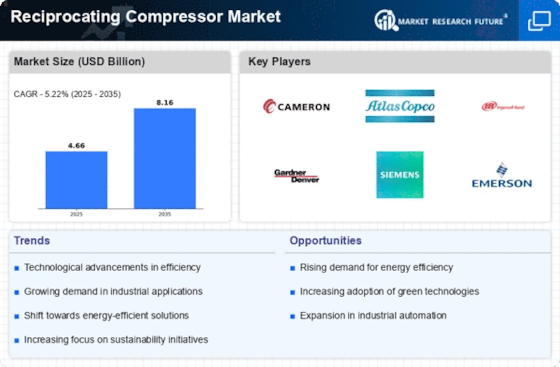

The oil and gas sector continues to exhibit a robust demand for reciprocating compressors, primarily due to their efficiency in handling high-pressure applications. As exploration and production activities expand, the need for reliable compression solutions becomes paramount. In 2025, the reciprocating compressor market is projected to witness a growth rate of approximately 5.2%, driven by the increasing investments in upstream oil and gas projects. This trend indicates a sustained reliance on reciprocating compressors for gas processing and transportation, thereby solidifying their role in the energy sector.

Emerging Applications in Renewable Energy

The reciprocating compressor market is witnessing emerging applications in the renewable energy sector, particularly in hydrogen production and storage. As the world shifts towards sustainable energy solutions, the demand for efficient compression technologies is likely to rise. In 2025, the market may experience a growth rate of approximately 6% due to the increasing focus on hydrogen as a clean energy carrier. This trend suggests that reciprocating compressors will play a vital role in facilitating the transition to renewable energy sources, thereby expanding their application scope.

Regulatory Compliance and Safety Standards

The increasing emphasis on regulatory compliance and safety standards is influencing the reciprocating compressor market. Industries are required to adhere to stringent safety regulations, which necessitate the use of reliable and efficient compression systems. In 2025, the market is expected to grow as companies invest in advanced reciprocating compressors that meet these regulatory requirements. This trend indicates a shift towards higher quality and safer equipment, as businesses prioritize compliance to avoid penalties and ensure operational safety. Consequently, the demand for reciprocating compressors that align with these standards is likely to rise.

Growth in Refrigeration and Air Conditioning

The refrigeration and air conditioning sectors are experiencing notable growth, which significantly impacts the reciprocating compressor market. With rising temperatures and changing climate patterns, the demand for efficient cooling systems is escalating. In 2025, the market for reciprocating compressors in these applications is expected to grow by around 4.8%. This growth is attributed to the increasing adoption of energy-efficient technologies and the need for reliable cooling solutions in both residential and commercial settings. Consequently, reciprocating compressors are becoming integral to modern refrigeration systems.

Industrial Automation and Process Optimization

The trend towards industrial automation and process optimization is reshaping the reciprocating compressor market. Industries are increasingly adopting automated systems to enhance operational efficiency and reduce costs. In 2025, the market is likely to see a surge in demand for reciprocating compressors that can integrate seamlessly with automated processes. This shift is driven by the need for precise control over compression processes, which reciprocating compressors can provide. As industries seek to optimize their operations, the role of these compressors in maintaining efficiency and reliability becomes increasingly critical.