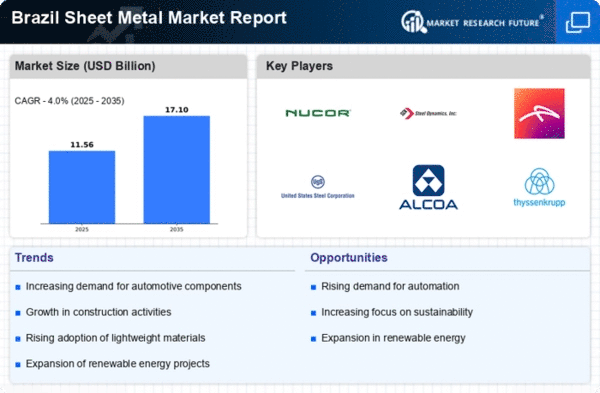

The sheet metal market in Brazil is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as Nucor Corporation (US), ArcelorMittal (LU), and Thyssenkrupp AG (DE) are actively pursuing strategies that emphasize technological advancement and operational efficiency. Nucor Corporation (US) has positioned itself as a leader in sustainable steel production, focusing on recycling and reducing carbon emissions, which aligns with global trends towards environmental responsibility. Meanwhile, ArcelorMittal (LU) continues to leverage its extensive global network to enhance its supply chain capabilities, thereby improving its market responsiveness. Thyssenkrupp AG (DE) is also investing in digital transformation initiatives, aiming to optimize its manufacturing processes and enhance product quality, which collectively influences the competitive dynamics of the market.The business tactics employed by these companies reflect a concerted effort to localize manufacturing and optimize supply chains. The market structure appears moderately fragmented, with several players vying for market share while also collaborating on sustainability initiatives. This collective influence of key players fosters a competitive environment where innovation and operational excellence are paramount, allowing companies to differentiate themselves in a crowded marketplace.

In September Nucor Corporation (US) announced a significant investment in a new recycling facility in Brazil, aimed at increasing its production capacity for sustainable sheet metal products. This strategic move not only enhances Nucor's operational footprint in the region but also underscores its commitment to sustainability, potentially positioning the company as a preferred supplier for environmentally conscious customers.

In October ArcelorMittal (LU) launched a new line of high-strength sheet metal products tailored for the automotive sector, which is experiencing a surge in demand for lightweight materials. This initiative is strategically important as it allows ArcelorMittal to capitalize on the growing trend towards electric vehicles, where weight reduction is critical for efficiency and performance.

In August Thyssenkrupp AG (DE) entered into a partnership with a local technology firm to develop AI-driven solutions for predictive maintenance in its manufacturing plants. This collaboration is likely to enhance operational efficiency and reduce downtime, thereby improving overall productivity and reinforcing Thyssenkrupp's competitive edge in the market.

As of November the competitive trends in the sheet metal market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are becoming more prevalent, enabling companies to pool resources and expertise to address complex market challenges. Looking ahead, it is anticipated that competitive differentiation will evolve from traditional price-based competition to a focus on innovation, technological advancement, and supply chain reliability, reflecting the changing demands of the market.