Technological Innovations

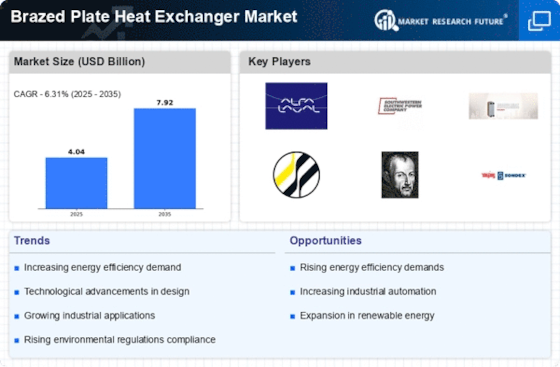

Technological advancements in the design and manufacturing of brazed plate heat exchangers are contributing to the growth of the Brazed Plate Heat Exchanger Market. Innovations such as improved brazing techniques and the use of advanced materials are enhancing the performance and durability of these heat exchangers. Manufacturers are increasingly adopting automation and smart technologies in production processes, which not only improves efficiency but also reduces costs. The introduction of simulation software for design optimization is also noteworthy, as it allows for the creation of more efficient and compact heat exchangers. As these technologies evolve, they are likely to attract more investments and drive market expansion in the Brazed Plate Heat Exchanger Market.

Increasing Industrialization

The ongoing trend of industrialization across various sectors appears to be a primary driver for the Brazed Plate Heat Exchanger Market. As industries expand, the demand for efficient heat transfer solutions rises, particularly in sectors such as chemical processing, food and beverage, and HVAC. The need for compact and efficient heat exchangers is becoming more pronounced, as companies seek to optimize their operations and reduce energy consumption. According to recent data, the industrial sector is projected to grow at a rate of approximately 4% annually, which could further bolster the demand for brazed plate heat exchangers. This growth indicates a robust market potential for manufacturers and suppliers within the Brazed Plate Heat Exchanger Market.

Growth in Renewable Energy Sector

The expansion of the renewable energy sector is poised to influence the Brazed Plate Heat Exchanger Market positively. As countries invest in renewable energy sources such as solar and wind, the need for efficient heat transfer solutions becomes paramount. Brazed plate heat exchangers are increasingly utilized in these applications due to their ability to handle varying temperatures and pressures effectively. The renewable energy market is expected to witness a growth rate of approximately 6% annually, which could lead to increased demand for heat exchangers that support these technologies. This growth trajectory indicates a promising opportunity for the Brazed Plate Heat Exchanger Market to align with the evolving energy landscape.

Rising Demand in HVAC Applications

The growing demand for heating, ventilation, and air conditioning (HVAC) systems is a significant driver for the Brazed Plate Heat Exchanger Market. As urbanization continues to rise, the need for efficient HVAC solutions becomes increasingly critical. Brazed plate heat exchangers are favored in HVAC applications due to their compact size and high efficiency, which help in optimizing space and energy use. The HVAC market is projected to grow at a compound annual growth rate of around 5% over the next few years, indicating a robust demand for heat exchangers. This trend suggests that the Brazed Plate Heat Exchanger Market will likely experience substantial growth as HVAC systems evolve to meet modern energy standards.

Environmental Regulations and Sustainability

The increasing emphasis on environmental regulations and sustainability initiatives is likely to propel the Brazed Plate Heat Exchanger Market. Governments and organizations are implementing stricter regulations aimed at reducing carbon emissions and promoting energy efficiency. Brazed plate heat exchangers, known for their high thermal efficiency and compact design, align well with these sustainability goals. The market is witnessing a shift towards eco-friendly technologies, and companies are investing in heat exchangers that minimize energy waste. This trend is expected to drive the market growth, as industries seek to comply with regulations while enhancing their operational efficiency. The Brazed Plate Heat Exchanger Market stands to benefit from this growing focus on sustainability.