Increased Focus on Aesthetic Appeal

Aesthetic considerations are becoming increasingly paramount in the Automotive Backlight Molding Market, as consumers seek vehicles that not only perform well but also look appealing. The integration of backlight molding technology allows for more intricate designs and finishes, enhancing the overall visual appeal of vehicles. This trend is particularly evident in premium and luxury segments, where manufacturers are investing in high-quality backlight solutions to differentiate their products. Market data suggests that the aesthetic segment of the automotive industry is projected to grow by 4% annually, indicating a robust demand for innovative backlight molding solutions that cater to design preferences. As a result, companies are likely to invest in research and development to create more visually striking backlight components.

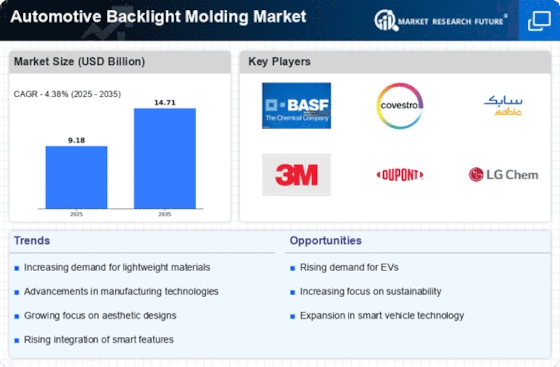

Rising Demand for Lightweight Materials

The Automotive Backlight Molding Market is experiencing a notable shift towards lightweight materials, driven by the automotive sector's focus on enhancing fuel efficiency and reducing emissions. Manufacturers are increasingly adopting advanced polymers and composites that not only reduce weight but also maintain structural integrity. This trend is underscored by the fact that lighter vehicles can achieve better fuel economy, which is a critical factor for consumers and regulatory bodies alike. As a result, the demand for innovative backlight molding solutions that utilize these materials is expected to rise, potentially leading to a market growth rate of approximately 5% annually over the next few years. This shift towards lightweight solutions is likely to redefine manufacturing processes and material selection in the Automotive Backlight Molding Market.

Growth of Electric and Autonomous Vehicles

The rise of electric and autonomous vehicles is significantly influencing the Automotive Backlight Molding Market. As the automotive landscape shifts towards electrification and automation, there is a growing need for advanced backlight solutions that cater to the unique design and functional requirements of these vehicles. Electric vehicles often require lightweight and efficient backlight systems to optimize battery performance, while autonomous vehicles demand sophisticated sensor integration within backlight components. Market analysts project that the electric vehicle segment will grow at a compound annual growth rate of over 20% in the coming years, which will likely drive demand for innovative backlight molding solutions tailored to these advanced vehicle types. This trend presents a substantial opportunity for manufacturers in the Automotive Backlight Molding Market.

Regulatory Compliance and Safety Standards

The Automotive Backlight Molding Market is increasingly influenced by stringent regulatory compliance and safety standards. Governments worldwide are implementing regulations aimed at improving vehicle safety and environmental performance, which directly impacts the materials and processes used in automotive manufacturing. Compliance with these regulations often necessitates the adoption of advanced backlight molding technologies that meet safety and environmental criteria. For instance, the use of non-toxic materials and energy-efficient production methods is becoming a requirement. This regulatory landscape is expected to drive innovation and investment in the Automotive Backlight Molding Market, as manufacturers strive to meet these evolving standards while maintaining competitiveness.

Technological Innovations in Manufacturing Processes

Technological advancements are playing a crucial role in shaping the Automotive Backlight Molding Market. Innovations such as 3D printing and advanced injection molding techniques are streamlining production processes, reducing lead times, and enhancing product quality. These technologies enable manufacturers to produce complex geometries and customized solutions that meet specific consumer demands. Furthermore, the adoption of automation and robotics in manufacturing is expected to improve efficiency and reduce costs, making it easier for companies to scale production. As these technologies continue to evolve, they are likely to drive a competitive edge in the Automotive Backlight Molding Market, with companies that embrace these innovations potentially capturing a larger market share.