Integration of Smart Technologies

The integration of smart technologies into the Automotive 3D Printed Tire Market Industry is emerging as a pivotal driver of growth. The incorporation of sensors and IoT capabilities into tires allows for real-time monitoring of tire performance, pressure, and wear. This data-driven approach enhances safety and efficiency, providing valuable insights for both manufacturers and consumers. As vehicles become increasingly connected, the demand for smart tires is expected to rise, leading to greater adoption of 3D printed solutions that can accommodate these technologies. The potential for enhanced performance and safety features positions smart tires as a key area of innovation within the Automotive 3D Printed Tire Market Industry, suggesting a promising future for manufacturers who embrace these advancements.

Advancements in 3D Printing Technology

Technological advancements in 3D printing are propelling the Automotive 3D Printed Tire Market Industry forward. Innovations such as improved printing speeds, enhanced material properties, and the ability to create complex geometries are transforming tire manufacturing. These advancements allow for the production of tires that are not only more efficient but also tailored to specific vehicle requirements. The integration of artificial intelligence and machine learning in the design process further optimizes tire performance and durability. As these technologies continue to evolve, they are expected to reduce production costs and time, making 3D printed tires more accessible to manufacturers. This evolution in technology is likely to stimulate market growth, with projections indicating a significant increase in adoption rates among automotive companies.

Customization and Consumer Preferences

The Automotive 3D Printed Tire Market Industry is witnessing a growing trend towards customization, driven by changing consumer preferences. Modern consumers are increasingly seeking personalized products that cater to their specific needs and tastes. 3D printing technology enables manufacturers to create tires that can be customized in terms of design, performance characteristics, and even tread patterns. This level of personalization not only enhances customer satisfaction but also allows for the development of niche products tailored to specific vehicle types or driving conditions. As the demand for customized solutions continues to rise, manufacturers are likely to invest more in 3D printing capabilities, further propelling the growth of the Automotive 3D Printed Tire Market Industry.

Rising Demand for Lightweight Materials

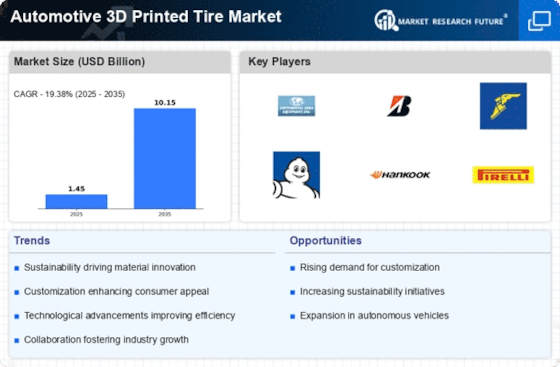

The Automotive 3D Printed Tire Market Industry is experiencing a notable shift towards lightweight materials, driven by the automotive sector's quest for enhanced fuel efficiency and performance. Tires produced through 3D printing techniques often utilize advanced polymers and composites that significantly reduce weight compared to traditional manufacturing methods. This reduction in weight not only improves vehicle efficiency but also contributes to lower emissions, aligning with regulatory standards. As manufacturers increasingly adopt these materials, the market for 3D printed tires is projected to grow, with estimates suggesting a compound annual growth rate of over 20% in the coming years. This trend indicates a strong potential for innovation in tire design and functionality, making lightweight materials a key driver in the Automotive 3D Printed Tire Market Industry.

Environmental Regulations and Sustainability

The Automotive 3D Printed Tire Market Industry is increasingly influenced by stringent environmental regulations aimed at reducing carbon footprints and promoting sustainability. Governments worldwide are implementing policies that encourage the use of eco-friendly materials and manufacturing processes. 3D printing technology aligns well with these initiatives, as it minimizes waste and allows for the use of recycled materials in tire production. Furthermore, the ability to produce tires on-demand reduces the need for large inventories, thereby decreasing resource consumption. As consumers become more environmentally conscious, the demand for sustainable tire solutions is expected to rise. This shift towards sustainability is likely to drive growth in the Automotive 3D Printed Tire Market Industry, with manufacturers seeking to meet both regulatory requirements and consumer expectations.