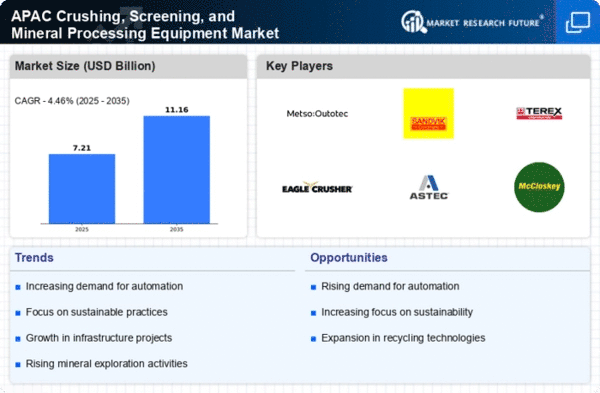

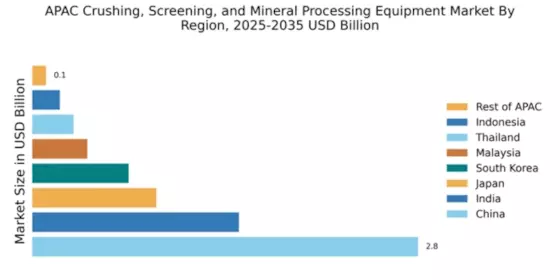

China : Unmatched Growth and Demand Trends

Key markets include major cities like Beijing, Shanghai, and Shenzhen, where construction activities are booming. The competitive landscape features major players like Metso Outotec and Sandvik, who have established strong footholds. Local dynamics are characterized by a mix of state-owned enterprises and private firms, fostering a competitive environment. The mining and construction industries are the primary sectors driving demand, with increasing investments in mineral processing technologies to enhance efficiency and sustainability.

India : Infrastructure Push Fuels Demand

Key markets include states like Maharashtra, Gujarat, and Karnataka, where construction and mining activities are concentrated. The competitive landscape features players like Terex Corporation and FLSmidth, who are actively expanding their presence. Local market dynamics are influenced by a mix of domestic and international firms, creating a vibrant business environment. The construction and mining sectors are the primary applications driving demand, with a focus on innovative and efficient processing technologies.

Japan : Innovation Drives Competitive Advantage

Key markets include Tokyo, Osaka, and Nagoya, where industrial activities are concentrated. The competitive landscape is dominated by local players like Sandvik and Thyssenkrupp, who leverage advanced technologies to maintain their market position. Local dynamics are shaped by a strong focus on R&D and innovation, fostering a conducive business environment. The construction and recycling industries are significant sectors driving demand, with increasing investments in sustainable processing solutions.

South Korea : Infrastructure Development Boosts Growth

Key markets include Seoul, Busan, and Incheon, where construction activities are concentrated. The competitive landscape features major players like McCloskey International and Astec Industries, who are expanding their market presence. Local dynamics are influenced by a mix of domestic and international firms, creating a competitive environment. The construction and mining sectors are the primary applications driving demand, with a focus on innovative processing technologies to enhance efficiency.

Malaysia : Strategic Location for Trade

Key markets include Kuala Lumpur, Johor, and Penang, where industrial activities are concentrated. The competitive landscape features players like Eagle Crusher Company and FLSmidth, who are actively expanding their presence. Local market dynamics are characterized by a mix of domestic and international firms, fostering a vibrant business environment. The construction and mining sectors are significant applications driving demand, with increasing investments in efficient processing technologies.

Thailand : Infrastructure Investments Drive Demand

Key markets include Bangkok, Chiang Mai, and Phuket, where construction activities are concentrated. The competitive landscape features players like Metso Outotec and Sandvik, who have established strong footholds. Local dynamics are shaped by a mix of domestic and international firms, creating a competitive environment. The construction and mining sectors are the primary applications driving demand, with a focus on innovative processing technologies to enhance efficiency.

Indonesia : Mining Sector Drives Equipment Demand

Key markets include Jakarta, Surabaya, and Bandung, where mining and construction activities are concentrated. The competitive landscape features players like Terex Corporation and Astec Industries, who are expanding their market presence. Local dynamics are influenced by a mix of domestic and international firms, creating a vibrant business environment. The mining and construction sectors are significant applications driving demand, with increasing investments in efficient processing technologies.

Rest of APAC : Diverse Applications Across Regions

Key markets include emerging economies like Vietnam, Philippines, and Bangladesh, where construction and mining activities are growing. The competitive landscape features a mix of local and international players, creating a diverse business environment. Local dynamics are shaped by varying regulatory frameworks and market conditions, with the construction and mining sectors being the primary applications driving demand for specialized equipment.