Rising Demand for Coatings

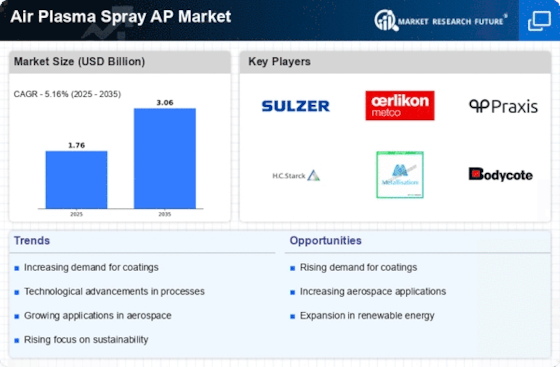

The Air Plasma Spray Market is experiencing a notable increase in demand for advanced coatings across various sectors. Industries such as aerospace, automotive, and energy are increasingly adopting plasma spray technologies to enhance the durability and performance of components. The market for thermal spray coatings is projected to reach approximately USD 12 billion by 2026, indicating a robust growth trajectory. This demand is driven by the need for improved wear resistance, corrosion protection, and thermal insulation in critical applications. As manufacturers seek to extend the lifespan of their products, the Air Plasma Spray Market is positioned to benefit significantly from this trend, as it offers innovative solutions that meet stringent performance standards.

Growth in Aerospace Applications

The aerospace sector is a key driver for the Air Plasma Spray Market, as it increasingly relies on advanced materials and coatings to enhance aircraft performance. The demand for lightweight, high-strength components is pushing manufacturers to adopt plasma spray technologies for turbine blades, engine components, and other critical parts. The aerospace coatings market is expected to grow at a CAGR of around 5% through 2027, reflecting the industry's commitment to innovation and efficiency. This growth is likely to be fueled by the ongoing advancements in plasma spray techniques, which enable the application of complex coatings that improve thermal barrier properties and reduce maintenance costs, thereby solidifying the Air Plasma Spray Market's role in aerospace advancements.

Expansion in Medical Applications

The Air Plasma Spray Market is witnessing an expansion into the medical sector, where advanced coatings are increasingly utilized for implants and surgical instruments. The demand for biocompatible coatings that enhance the performance and longevity of medical devices is driving this trend. The global market for medical coatings is anticipated to grow at a CAGR of approximately 6% over the next few years, reflecting the increasing need for innovative solutions in healthcare. Plasma spray technologies offer unique advantages, such as the ability to create porous coatings that promote osseointegration in implants. This expansion into medical applications suggests that the Air Plasma Spray Market is diversifying its offerings, thereby opening new avenues for growth and innovation.

Increasing Focus on Energy Efficiency

The push for energy efficiency is becoming a pivotal factor in the Air Plasma Spray Market. Industries are increasingly adopting plasma spray coatings to improve the thermal efficiency of components, particularly in the energy sector. Coatings that enhance heat resistance and reduce energy loss are in high demand, as they contribute to lower operational costs and improved sustainability. The energy efficiency market is projected to grow significantly, with investments in advanced materials and coatings expected to rise. This trend indicates that the Air Plasma Spray Market is likely to play a crucial role in supporting energy-efficient technologies, as manufacturers seek to comply with stringent regulations and reduce their carbon footprint.

Technological Innovations in Plasma Spray

Technological advancements in plasma spray processes are significantly influencing the Air Plasma Spray Market. Innovations such as the development of high-velocity oxygen fuel (HVOF) and cold spray techniques are enhancing the efficiency and effectiveness of coating applications. These technologies allow for better control over coating properties, leading to improved adhesion and reduced porosity. As a result, the market is witnessing a shift towards more sophisticated plasma spray systems that can cater to diverse industrial needs. The introduction of automated plasma spray systems is also streamlining production processes, thereby reducing operational costs. This trend suggests that the Air Plasma Spray Market is on the cusp of a technological revolution that could redefine coating applications across various sectors.