Market Trends and Projections

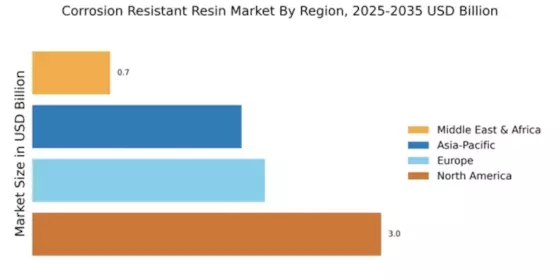

The Global Corrosion Resistant Resin Market Industry is projected to experience substantial growth, with estimates indicating a market value of 7.47 USD Billion in 2024 and a potential increase to 13.5 USD Billion by 2035. The anticipated CAGR of 5.55% from 2025 to 2035 suggests a steady upward trajectory, driven by various factors including technological advancements, infrastructure development, and increasing environmental awareness. These trends highlight the resilience and adaptability of the corrosion-resistant resin market, positioning it favorably for future opportunities.

Increasing Infrastructure Development

The Global Corrosion Resistant Resin Market Industry is significantly influenced by the ongoing infrastructure development across various regions. Governments and private entities are investing heavily in infrastructure projects, including bridges, roads, and buildings, which necessitate the use of durable materials resistant to corrosion. For instance, the construction of new highways and urban developments requires resins that can withstand environmental stressors. This trend is expected to bolster market growth, with forecasts suggesting a market size of 13.5 USD Billion by 2035, highlighting the critical role of corrosion-resistant resins in modern construction.

Rising Demand from End-User Industries

The Global Corrosion Resistant Resin Market Industry experiences heightened demand from various end-user sectors, including automotive, construction, and marine. These industries increasingly require materials that can withstand harsh environmental conditions, thereby driving the adoption of corrosion-resistant resins. For instance, the automotive sector is focusing on lightweight materials that offer durability and resistance to corrosion, which is crucial for enhancing vehicle longevity. This trend is expected to contribute to the market's growth, with projections indicating a market value of 7.47 USD Billion in 2024, reflecting the industry's commitment to innovation and sustainability.

Expansion of the Chemical Processing Industry

The Global Corrosion Resistant Resin Market Industry benefits from the expansion of the chemical processing sector, which requires materials that can withstand aggressive chemicals and extreme conditions. As the chemical industry grows, so does the demand for resins that offer superior corrosion resistance. Applications in pipelines, storage tanks, and processing equipment are increasingly reliant on these advanced materials. This trend is likely to drive market growth, as the chemical processing industry continues to evolve and expand, creating a robust demand for corrosion-resistant solutions.

Growing Awareness of Environmental Regulations

The Global Corrosion Resistant Resin Market Industry is increasingly shaped by stringent environmental regulations aimed at reducing the environmental impact of industrial processes. As industries face pressure to comply with these regulations, there is a growing preference for eco-friendly materials, including corrosion-resistant resins. This shift is particularly evident in sectors such as oil and gas, where regulations mandate the use of materials that minimize environmental harm. Consequently, manufacturers are adapting their product lines to meet these standards, which could lead to increased market penetration and growth opportunities in the coming years.

Technological Advancements in Resin Formulations

Innovations in resin formulations are propelling the Global Corrosion Resistant Resin Market Industry forward. Manufacturers are investing in research and development to create advanced resins that exhibit superior corrosion resistance and mechanical properties. For example, the introduction of bio-based resins and hybrid formulations is gaining traction, as they provide eco-friendly alternatives without compromising performance. These advancements not only enhance product offerings but also align with global sustainability goals, potentially expanding market reach. As a result, the industry is poised for growth, with a projected CAGR of 5.55% from 2025 to 2035, indicating a robust future.