North America : Leading Market Innovators

North America is poised to maintain its leadership in the Additive Manufacturing Services Market, holding a significant market share of 7.5 in 2024. The region's growth is driven by robust demand from industries such as aerospace, automotive, and healthcare, alongside supportive government initiatives promoting advanced manufacturing technologies. Regulatory frameworks are increasingly favorable, encouraging innovation and investment in 3D printing technologies.

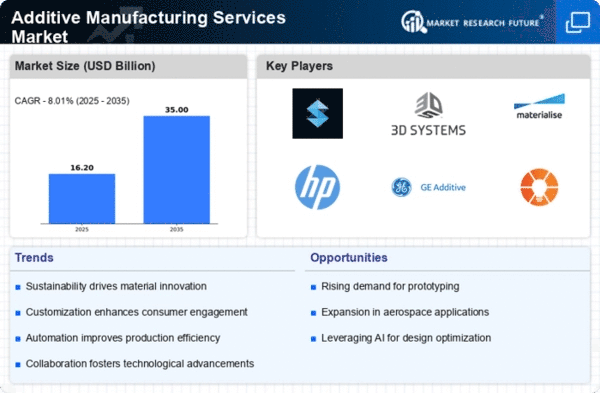

The competitive landscape is characterized by key players like Stratasys, 3D Systems, and GE Additive, which are at the forefront of technological advancements. The U.S. leads the market, supported by a strong ecosystem of research institutions and startups. This dynamic environment fosters collaboration and accelerates the adoption of additive manufacturing solutions across various sectors.

Europe : Emerging Regulatory Frameworks

Europe's Additive Manufacturing Services Market is projected to grow significantly, with a market size of 4.5 in 2024. The region benefits from a strong emphasis on sustainability and innovation, driven by EU regulations that promote eco-friendly manufacturing practices. Countries like Germany and France are leading the charge, with investments in R&D and initiatives aimed at enhancing the competitiveness of the manufacturing sector.

The competitive landscape features prominent players such as Materialise and EOS, which are leveraging advanced technologies to meet the rising demand for customized solutions. The presence of a skilled workforce and strong industrial base further supports market growth. As Europe continues to embrace additive manufacturing, it is expected to play a crucial role in shaping the future of manufacturing in the region.

Asia-Pacific : Rapidly Growing Market Potential

The Asia-Pacific region is witnessing rapid growth in the Additive Manufacturing Services Market, with a market size of 2.5 in 2024. Key drivers include increasing industrialization, a growing middle class, and rising demand for customized products. Countries like China and Japan are at the forefront, investing heavily in additive manufacturing technologies to enhance production efficiency and reduce costs.

The competitive landscape is evolving, with local players emerging alongside established global companies. The presence of key players such as HP and Desktop Metal is fostering innovation and collaboration. As the region continues to develop its manufacturing capabilities, the adoption of additive manufacturing is expected to accelerate, positioning Asia-Pacific as a significant player in the global market.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region is in the nascent stages of developing its Additive Manufacturing Services Market, with a market size of 0.5 in 2024. Growth is driven by increasing investments in technology and infrastructure, alongside a rising interest in 3D printing applications across various sectors, including healthcare and construction. Governments are beginning to recognize the potential of additive manufacturing to diversify their economies and reduce reliance on traditional industries.

Countries like the UAE and South Africa are leading the way, with initiatives aimed at fostering innovation and attracting foreign investment. The competitive landscape is still developing, but the presence of global players is beginning to influence local markets. As awareness and capabilities grow, the region is expected to unlock significant opportunities in additive manufacturing.