Regulatory Support

Regulatory support is emerging as a significant driver for the 3D Printed Nanocellulose Market. Governments and regulatory bodies are increasingly recognizing the potential of nanocellulose as a sustainable material, leading to favorable policies and funding initiatives. For instance, various countries are implementing regulations that promote the use of biodegradable materials in packaging and construction, which directly benefits the nanocellulose market. The European Union's Green Deal aims to make Europe climate-neutral by 2050, which could further incentivize the adoption of eco-friendly materials like nanocellulose. This supportive regulatory environment not only encourages investment in research and development but also fosters collaboration between public and private sectors, ultimately propelling the growth of the 3D printed nanocellulose market.

Sustainability Initiatives

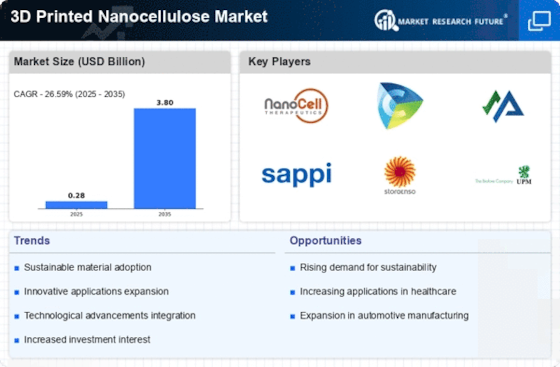

The increasing emphasis on sustainability is a pivotal driver for the 3D Printed Nanocellulose Market. As industries strive to reduce their carbon footprints, nanocellulose, derived from renewable resources, presents an eco-friendly alternative to traditional materials. The market for bioplastics, which includes nanocellulose, is projected to reach USD 44 billion by 2026, indicating a robust growth trajectory. This shift towards sustainable materials not only aligns with regulatory pressures but also resonates with consumer preferences for environmentally responsible products. Consequently, manufacturers are increasingly adopting 3D printed nanocellulose to meet these demands, thereby enhancing their market positioning. The integration of nanocellulose in various applications, from packaging to construction, further underscores its potential in promoting sustainability across multiple sectors.

Technological Advancements

Technological advancements are a crucial driver for the 3D Printed Nanocellulose Market. Innovations in 3D printing technologies, such as improved printing speeds and enhanced material properties, are facilitating the broader adoption of nanocellulose in various applications. The development of advanced printing techniques, including multi-material printing, allows for the creation of complex structures that were previously unattainable. As a result, the market is witnessing a surge in applications ranging from biomedical devices to automotive components. The global 3D printing market is projected to grow to USD 34.8 billion by 2024, indicating a strong demand for innovative materials like nanocellulose. These technological strides not only enhance the performance of 3D printed products but also expand the potential applications of nanocellulose, thereby driving market growth.

Customization and Personalization

Customization and personalization are becoming increasingly vital in the 3D Printed Nanocellulose Market. As consumers seek unique products tailored to their specific needs, the ability to 3D print nanocellulose allows for unprecedented design flexibility. This capability is particularly advantageous in sectors such as healthcare, where personalized medical devices and implants are gaining traction. The market for personalized medicine is expected to grow significantly, potentially reaching USD 2.4 trillion by 2025. This trend not only enhances consumer satisfaction but also drives innovation within the industry, as companies invest in advanced 3D printing technologies to cater to diverse customer preferences. The ability to produce bespoke solutions using nanocellulose could redefine product offerings and create new revenue streams for manufacturers.

Market Demand for Lightweight Materials

The growing demand for lightweight materials is a prominent driver for the 3D Printed Nanocellulose Market. Industries such as aerospace, automotive, and consumer goods are increasingly seeking materials that offer high strength-to-weight ratios. Nanocellulose, known for its lightweight yet robust properties, is well-positioned to meet these requirements. The 3D Printed Nanocellulose Market is anticipated to reach USD 200 billion by 2025, highlighting the increasing preference for materials that enhance fuel efficiency and reduce emissions. As manufacturers adopt 3D printing technologies to produce lightweight components using nanocellulose, they can achieve significant cost savings and performance improvements. This trend not only supports sustainability goals but also drives innovation in product design and engineering, further stimulating the growth of the 3D printed nanocellulose market.