Market Growth Projections

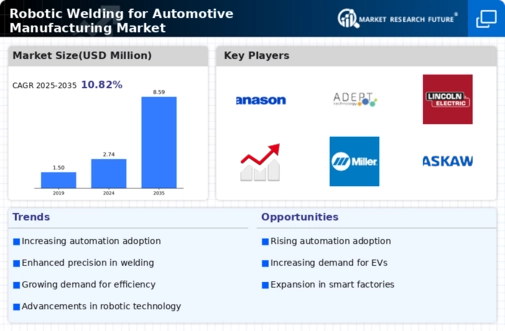

The Global Robotic Welding for Automotive Manufacturing Market Industry is projected to experience substantial growth over the coming years. With a market value of 2.74 USD Billion in 2024, the industry is expected to expand significantly, reaching 8.59 USD Billion by 2035. This growth trajectory indicates a compound annual growth rate (CAGR) of 10.94% from 2025 to 2035. Such projections reflect the increasing adoption of robotic welding technologies as manufacturers seek to enhance efficiency, reduce costs, and improve product quality. The robust growth forecast underscores the importance of robotic welding in the evolving landscape of automotive manufacturing.

Advancements in Technology

Technological innovations play a crucial role in the Global Robotic Welding for Automotive Manufacturing Market Industry. The integration of artificial intelligence and machine learning into robotic systems enhances their capabilities, allowing for real-time adjustments and improved precision. These advancements facilitate the welding of complex geometries and diverse materials, which are increasingly common in modern automotive designs. As manufacturers adopt these cutting-edge technologies, the market is expected to grow significantly, with projections indicating a rise to 8.59 USD Billion by 2035. This growth underscores the importance of staying at the forefront of technological development in the automotive manufacturing sector.

Focus on Quality and Consistency

Quality assurance remains a top priority within the Global Robotic Welding for Automotive Manufacturing Market Industry. Robotic welding systems provide a level of consistency and precision that is difficult to achieve with manual welding processes. This consistency not only enhances the structural integrity of automotive components but also reduces the likelihood of defects. As automotive manufacturers increasingly prioritize quality, the demand for robotic welding solutions is expected to rise. The projected compound annual growth rate (CAGR) of 10.94% from 2025 to 2035 reflects the industry's commitment to maintaining high standards through advanced welding technologies.

Increasing Demand for Automation

The Global Robotic Welding for Automotive Manufacturing Market Industry is experiencing a surge in demand for automation solutions. As manufacturers strive for enhanced productivity and efficiency, robotic welding systems offer significant advantages over traditional methods. These systems can operate continuously, reducing labor costs and minimizing human error. In 2024, the market is projected to reach 2.74 USD Billion, reflecting a growing trend towards automation in the automotive sector. This shift is driven by the need for consistent quality and the ability to meet increasing production volumes, which robotic welding systems can provide effectively.

Global Expansion of Automotive Production

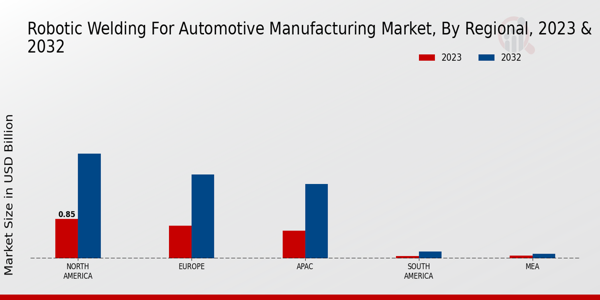

The Global Robotic Welding for Automotive Manufacturing Market Industry is benefiting from the expansion of automotive production across various regions. Emerging markets are witnessing a rise in automotive manufacturing activities, driven by increasing consumer demand and investment in infrastructure. This expansion necessitates the adoption of efficient manufacturing processes, including robotic welding. As manufacturers in these regions seek to enhance their production capabilities, the market for robotic welding solutions is poised for growth. The increasing global footprint of automotive manufacturers highlights the potential for robotic welding technologies to play a pivotal role in meeting production demands.

Regulatory Compliance and Safety Standards

The Global Robotic Welding for Automotive Manufacturing Market Industry is influenced by stringent regulatory compliance and safety standards. Governments worldwide are implementing regulations that mandate higher safety and environmental standards in manufacturing processes. Robotic welding systems not only enhance workplace safety by minimizing human involvement in hazardous tasks but also contribute to cleaner production methods. As manufacturers adapt to these regulations, the adoption of robotic welding technologies is likely to increase. This trend is expected to further drive market growth as companies seek to comply with evolving standards while maintaining operational efficiency.