Technological Advancements

The Global Gear Manufacturing Market Industry is experiencing a surge in technological advancements, particularly in automation and precision engineering. Innovations such as computer numerical control (CNC) machining and additive manufacturing are enhancing production efficiency and accuracy. These technologies allow manufacturers to produce complex gear designs that were previously unattainable, thereby expanding their product offerings. As a result, the market is projected to reach 247.6 USD Billion in 2024, reflecting the industry's adaptation to modern manufacturing techniques. This shift not only improves operational efficiency but also reduces production costs, positioning companies to compete effectively in a globalized market.

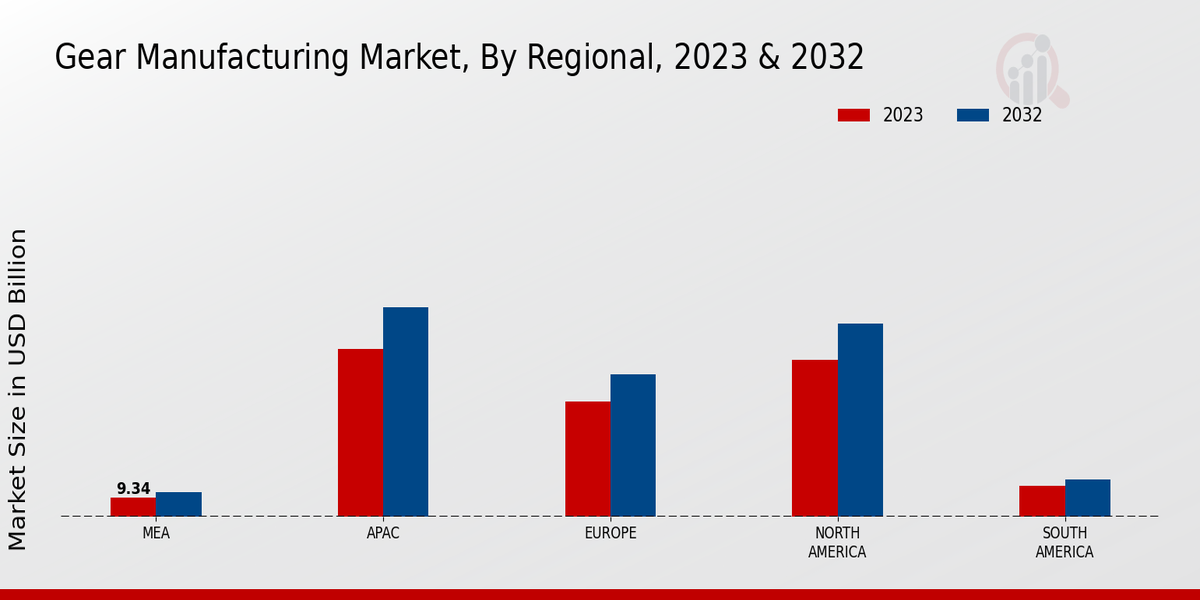

Market Trends and Projections

The Global Gear Manufacturing Market Industry is poised for growth, with projections indicating a market size of 247.6 USD Billion in 2024 and an anticipated increase to 334.8 USD Billion by 2035. The compound annual growth rate (CAGR) of 2.78% from 2025 to 2035 suggests a steady upward trajectory, driven by various factors including technological advancements, rising demand from key sectors, and the expansion of industrial automation. These trends indicate a robust future for the gear manufacturing sector, as companies adapt to changing market dynamics and consumer needs.

Expansion of Aerospace Industry

The aerospace industry is another critical driver of the Global Gear Manufacturing Market Industry. With the increasing demand for air travel and advancements in aerospace technology, the need for high-performance gears is becoming more pronounced. Gears are integral components in aircraft systems, influencing safety and efficiency. As the aerospace sector continues to expand, manufacturers are likely to see a rise in orders for specialized gear systems designed to meet stringent regulatory standards. This growth not only supports the market's overall expansion but also encourages innovation in gear design and materials to enhance performance and reliability.

Growing Renewable Energy Sector

The growing emphasis on renewable energy sources is influencing the Global Gear Manufacturing Market Industry. Wind and solar energy systems require specialized gears for their operation, particularly in wind turbines where gearboxes are essential for energy conversion. As countries invest in sustainable energy infrastructure, the demand for high-quality gears is expected to rise. This trend aligns with global efforts to reduce carbon emissions and transition towards greener technologies. The market's growth in this sector presents opportunities for gear manufacturers to diversify their portfolios and cater to the evolving energy landscape.

Increased Industrial Automation

The trend towards increased industrial automation is reshaping the Global Gear Manufacturing Market Industry. As industries strive for greater efficiency and productivity, the demand for automated machinery and equipment is on the rise. Gears play a crucial role in these systems, facilitating smooth operations in various applications, from manufacturing to logistics. The anticipated compound annual growth rate (CAGR) of 2.78% from 2025 to 2035 indicates a steady growth trajectory for the market, driven by the need for reliable gear solutions in automated processes. This shift not only enhances operational efficiency but also reduces labor costs, making automation an attractive proposition for manufacturers.

Rising Demand from Automotive Sector

The automotive sector is a primary driver of the Global Gear Manufacturing Market Industry, accounting for a substantial share of gear consumption. With the ongoing transition towards electric vehicles (EVs) and hybrid technologies, the demand for specialized gears is likely to increase. This sector's growth is projected to contribute significantly to the market, which is expected to reach 334.8 USD Billion by 2035. The automotive industry's focus on enhancing fuel efficiency and performance necessitates the development of advanced gear systems, thereby creating opportunities for gear manufacturers to innovate and expand their product lines.