Market Growth Projections

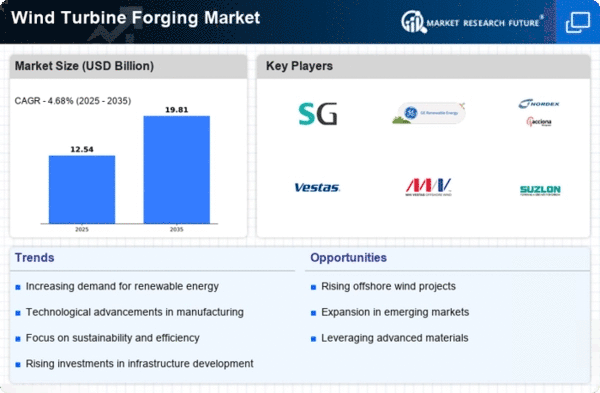

The Global Wind Turbine Forging Market Industry is projected to experience substantial growth in the coming years. With a market value of 11.4 USD Billion anticipated in 2024, the industry is set to expand further, driven by increasing investments in wind energy and technological advancements. The compound annual growth rate of 4.7% from 2025 to 2035 indicates a robust market trajectory, suggesting that the demand for forged components will continue to rise as wind energy becomes a more prominent part of the global energy mix. This growth reflects the industry's adaptability and responsiveness to evolving energy needs.

Growing Focus on Energy Security

The increasing focus on energy security amid geopolitical tensions and fluctuating fossil fuel prices is propelling the Global Wind Turbine Forging Market Industry. Nations are seeking to diversify their energy sources to ensure a stable supply, leading to a heightened interest in wind energy as a viable alternative. This shift is evident in various countries ramping up investments in wind infrastructure, which subsequently drives the demand for forged components. As energy security becomes a priority, the market is poised for growth, potentially reaching a valuation of 18.9 USD Billion by 2035, reflecting the critical role of forging in the renewable energy landscape.

Increasing Offshore Wind Projects

The expansion of offshore wind projects significantly influences the Global Wind Turbine Forging Market Industry. Offshore wind farms require specialized turbine components that can withstand harsh marine environments, leading to a higher demand for high-quality forged materials. Countries like the United Kingdom and Germany are investing heavily in offshore wind capacity, with projections indicating that offshore installations could account for over 30% of total wind energy capacity by 2030. This trend not only enhances the market potential but also emphasizes the need for advanced forging techniques to meet specific requirements, thereby driving growth in the sector.

Rising Demand for Renewable Energy

The increasing global emphasis on renewable energy sources drives the Global Wind Turbine Forging Market Industry. Governments worldwide are implementing policies to reduce carbon emissions, leading to a surge in wind energy projects. For instance, the global wind energy capacity is projected to reach approximately 1,000 GW by 2024, necessitating robust and durable components produced through forging. This trend is expected to contribute to the market's growth, with the industry projected to reach 11.4 USD Billion in 2024. The shift towards cleaner energy solutions indicates a sustained demand for wind turbines, thereby bolstering the forging sector.

Government Incentives and Subsidies

Government incentives and subsidies for renewable energy projects play a crucial role in the growth of the Global Wind Turbine Forging Market Industry. Many countries offer financial support to encourage the development of wind energy infrastructure, which in turn stimulates demand for forged components. For example, the United States has implemented tax credits and grants for wind energy projects, significantly boosting investments in the sector. This supportive regulatory environment is expected to drive the market's growth, with a projected compound annual growth rate of 4.7% from 2025 to 2035. Such initiatives indicate a favorable landscape for the forging industry.

Technological Advancements in Forging Processes

Innovations in forging technologies enhance the efficiency and quality of components used in wind turbines, positively impacting the Global Wind Turbine Forging Market Industry. Advanced techniques such as precision forging and automated processes allow manufacturers to produce lighter and stronger materials, which are essential for modern wind turbine designs. These advancements not only improve performance but also reduce production costs. As the industry evolves, the market is likely to benefit from these technological improvements, which could lead to an estimated market value of 18.9 USD Billion by 2035. The integration of new technologies suggests a promising future for the forging sector.