Rising Demand for Skilled Labor

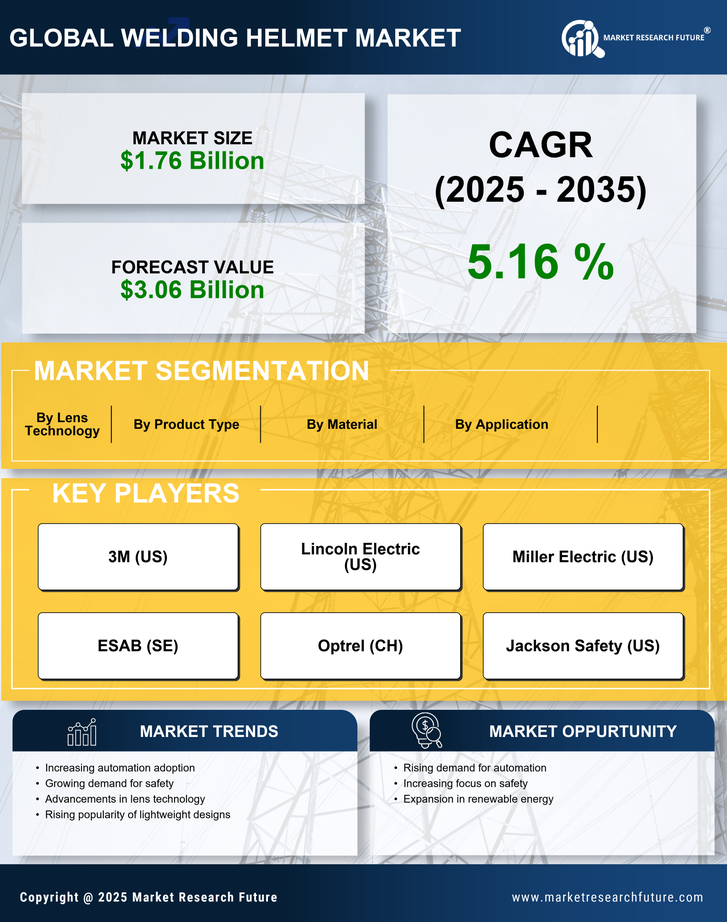

The Welding Helmet Market experiences a notable increase in demand for skilled labor across various sectors, including construction, manufacturing, and automotive. As industries expand, the need for qualified welders rises, driving the demand for protective equipment such as welding helmets. According to recent data, the welding workforce is projected to grow by approximately 6% over the next decade, which may lead to a corresponding increase in helmet sales. This trend suggests that as more individuals enter the welding profession, the Welding Helmet Market will likely see a surge in product innovation and variety to meet the needs of a diverse workforce.

Emergence of Eco-Friendly Products

The Welding Helmet Market is increasingly influenced by the emergence of eco-friendly products. As sustainability becomes a priority for many industries, manufacturers are exploring ways to produce welding helmets using environmentally friendly materials and processes. This shift is not only appealing to environmentally conscious consumers but also aligns with corporate sustainability goals. Recent data suggests that the market for sustainable welding products is expected to grow, as companies seek to reduce their carbon footprint. Consequently, the Welding Helmet Market may see a rise in demand for helmets that are both effective and environmentally responsible, reflecting a broader trend towards sustainability.

Increased Awareness of Workplace Safety

The Welding Helmet Market is witnessing a surge in awareness regarding workplace safety. As industries become more cognizant of the risks associated with welding, there is a growing emphasis on protective gear. Regulatory bodies are enforcing stricter safety standards, compelling companies to invest in high-quality welding helmets. Recent surveys indicate that a significant percentage of employers are prioritizing safety training and equipment procurement, which may lead to increased sales in the Welding Helmet Market. This heightened focus on safety not only protects workers but also enhances productivity, as safer environments contribute to fewer accidents and downtime.

Technological Innovations in Welding Equipment

Technological innovations play a crucial role in shaping the Welding Helmet Market. Advancements in materials and design have led to the development of lightweight, durable, and more effective welding helmets. Features such as auto-darkening lenses and enhanced visibility are becoming standard, appealing to both professional and amateur welders. The integration of smart technology, such as augmented reality, is also emerging, potentially revolutionizing the way welders operate. As these innovations continue to evolve, they are likely to attract new customers and retain existing ones, thereby propelling the growth of the Welding Helmet Market.

Growth in Construction and Manufacturing Sectors

The Welding Helmet Market is significantly influenced by the growth in construction and manufacturing sectors. As infrastructure projects and manufacturing activities ramp up, the demand for welding services escalates, thereby increasing the need for high-quality welding helmets. Recent statistics indicate that the construction sector alone is expected to grow at a compound annual growth rate of around 5% over the next few years. This growth is likely to drive investments in safety equipment, including welding helmets, as companies prioritize worker safety and compliance with regulations. Consequently, the Welding Helmet Market stands to benefit from this upward trend.