Advancements in Robotics Technology

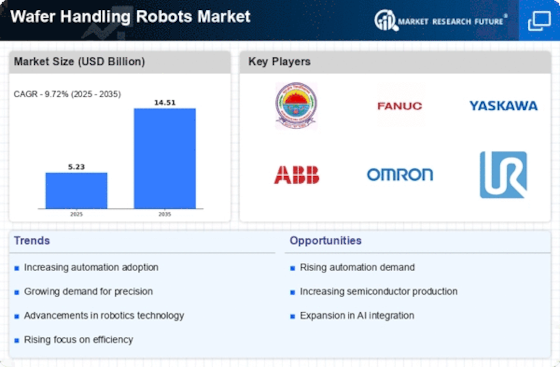

Technological advancements in robotics are significantly influencing the Wafer Handling Robots Market. Innovations such as enhanced sensors, improved automation algorithms, and sophisticated control systems are enabling robots to perform complex tasks with greater accuracy and efficiency. For instance, the introduction of collaborative robots, or cobots, allows for safer interactions between human operators and robotic systems. This evolution in robotics technology is expected to drive market growth, as manufacturers seek to adopt cutting-edge solutions to remain competitive. The market for industrial robots, which includes wafer handling robots, is projected to grow at a CAGR of 10% through 2027, indicating a robust demand for advanced robotic solutions in semiconductor manufacturing.

Rising Demand for Semiconductor Devices

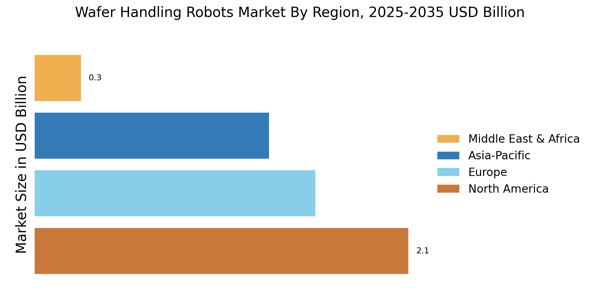

The Wafer Handling Robots Market is experiencing a surge in demand driven by the increasing need for semiconductor devices across various sectors, including consumer electronics, automotive, and telecommunications. As the proliferation of smart devices continues, manufacturers are compelled to enhance production efficiency and precision. This trend is reflected in the projected growth of the semiconductor market, which is expected to reach USD 1 trillion by 2030. Consequently, the demand for wafer handling robots, which facilitate the delicate and precise handling of wafers during the manufacturing process, is likely to escalate. The integration of these robots not only improves throughput but also minimizes the risk of contamination, thereby ensuring higher quality standards in semiconductor production.

Increased Focus on Cleanroom Environments

The Wafer Handling Robots Market is significantly influenced by the stringent requirements for cleanroom environments in semiconductor manufacturing. As the industry strives to maintain high levels of cleanliness to prevent contamination, the adoption of wafer handling robots becomes essential. These robots are designed to operate in cleanroom conditions, minimizing human intervention and thereby reducing the risk of particulate contamination. The cleanroom equipment market is anticipated to grow substantially, with a projected value of USD 5 billion by 2026. This growth is likely to propel the demand for wafer handling robots, as manufacturers increasingly prioritize automation solutions that comply with cleanroom standards, ensuring the integrity of their production processes.

Growing Investment in Research and Development

Investment in research and development within the semiconductor sector is a key driver for the Wafer Handling Robots Market. As companies strive to innovate and develop next-generation semiconductor technologies, the need for advanced manufacturing solutions becomes paramount. This trend is evidenced by the substantial funding allocated to R&D, which is expected to reach USD 100 billion annually by 2025. Such investments are likely to foster the development of more sophisticated wafer handling robots that can accommodate the evolving demands of semiconductor fabrication. As manufacturers seek to enhance their production capabilities and maintain a competitive edge, the integration of advanced robotic systems will play a crucial role in their strategic initiatives.

Expansion of Semiconductor Manufacturing Facilities

The Wafer Handling Robots Market is poised for growth due to the expansion of semiconductor manufacturing facilities worldwide. As demand for chips continues to rise, manufacturers are investing in new production plants and upgrading existing facilities to increase capacity. This expansion is reflected in the construction of new fabs, with investments projected to exceed USD 200 billion over the next few years. Such developments necessitate the implementation of efficient and reliable wafer handling systems to optimize production processes. Consequently, the demand for wafer handling robots is expected to increase, as these systems are integral to the automation of wafer transport and processing, thereby enhancing overall operational efficiency in semiconductor manufacturing.