North America : Market Leader in MRO Services

North America is poised to maintain its leadership in the Industrial Heat Treatment Equipment MRO Services Market, holding a significant market share of 3.25 billion. The region's growth is driven by robust manufacturing sectors, technological advancements, and increasing demand for high-quality heat treatment processes. Regulatory support for industrial standards further catalyzes market expansion, ensuring compliance and safety in operations.

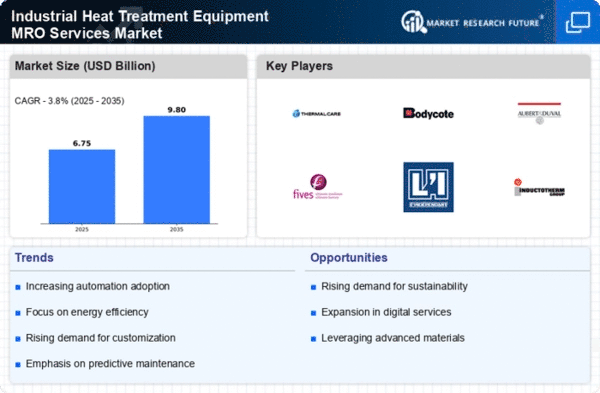

The competitive landscape is characterized by key players such as Thermal Care, Inductotherm Group, and Nitrex Metal, which are leveraging innovation to enhance service offerings. The U.S. stands out as the leading country, supported by a strong infrastructure and investment in R&D. This dynamic environment fosters collaboration among industry stakeholders, ensuring a steady supply of advanced MRO services to meet growing industrial needs.

Europe : Emerging Market with Growth Potential

Europe's Industrial Heat Treatment Equipment MRO Services Market is valued at 1.8 billion, reflecting a growing demand driven by the automotive and aerospace sectors. Regulatory frameworks, such as the EU's Machinery Directive, promote safety and efficiency, acting as catalysts for market growth. The increasing focus on sustainable practices and energy efficiency further enhances the appeal of heat treatment services across various industries.

Leading countries like Germany, France, and the UK are at the forefront of this market, with companies such as Bodycote and Aubert & Duval playing pivotal roles. The competitive landscape is marked by innovation and strategic partnerships, enabling firms to offer tailored solutions. As the region continues to invest in advanced technologies, the MRO services market is expected to expand, catering to diverse industrial needs.

Asia-Pacific : Rapidly Growing Industrial Sector

The Asia-Pacific region, with a market size of 1.7 billion, is witnessing rapid growth in the Industrial Heat Treatment Equipment MRO Services Market. This expansion is fueled by increasing industrialization, particularly in countries like China and India, where manufacturing activities are surging. The demand for high-quality heat treatment processes is rising, driven by the need for improved product performance and durability, supported by favorable government policies.

China leads the region, with significant investments in manufacturing and technology. The competitive landscape features key players like Linde and Seco Tools, who are focusing on innovation and service diversification. As the region embraces modernization and technological advancements, the MRO services market is set to thrive, catering to the evolving needs of various industries.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, valued at 0.65 billion, presents an emerging market for Industrial Heat Treatment Equipment MRO Services. The growth is driven by increasing industrial activities, particularly in oil and gas, and a rising focus on manufacturing capabilities. Regulatory initiatives aimed at enhancing industrial standards are expected to catalyze market development, creating opportunities for MRO service providers.

Countries like South Africa and the UAE are leading the charge, with investments in infrastructure and technology. The competitive landscape is still developing, with local and international players vying for market share. As the region continues to evolve, the demand for efficient heat treatment services is anticipated to grow, driven by the need for quality and reliability in industrial processes.