Expansion of End-User Industries

The UV-Curing System Market is significantly influenced by the expansion of end-user industries such as automotive, electronics, and packaging. As these sectors grow, the demand for UV-curing systems is expected to rise correspondingly. For instance, the automotive industry is increasingly utilizing UV-cured coatings for their durability and aesthetic appeal, while the electronics sector benefits from UV-curing in the production of circuit boards and components. The packaging industry is also adopting UV-curing technologies to enhance print quality and reduce production times. This diversification across various sectors is likely to create new opportunities for market players, with projections indicating a robust growth trajectory as these industries continue to evolve and innovate.

Increasing Demand for Eco-Friendly Solutions

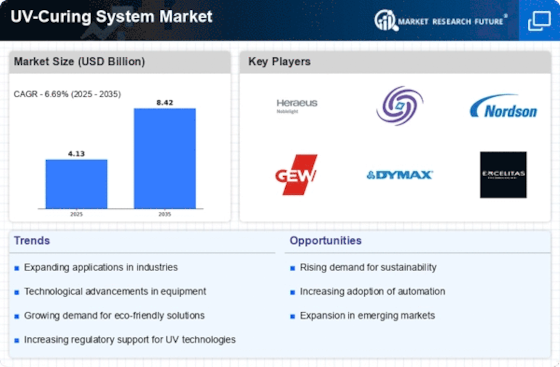

The UV-Curing System Market is experiencing a notable shift towards eco-friendly solutions. As industries become more aware of environmental impacts, there is a growing preference for UV-curing technologies that reduce volatile organic compounds (VOCs) and other harmful emissions. This trend is particularly evident in sectors such as printing, coatings, and adhesives, where traditional curing methods are being replaced by UV-curing systems. The market for UV-curing systems is projected to grow at a compound annual growth rate (CAGR) of approximately 8% over the next few years, driven by this demand for sustainable practices. Companies are increasingly investing in UV-curing technologies to enhance their product offerings while adhering to stringent environmental regulations. This shift not only aligns with corporate social responsibility goals but also meets consumer expectations for greener products.

Regulatory Support for UV-Curing Technologies

Regulatory frameworks are increasingly favoring the adoption of UV-Curing System Market technologies. Governments worldwide are implementing stricter regulations on emissions and environmental standards, which is driving industries to seek cleaner alternatives. UV-curing systems, known for their low emissions and energy efficiency, are becoming a preferred choice for manufacturers aiming to comply with these regulations. Additionally, incentives and subsidies for adopting green technologies are further encouraging the transition to UV-curing systems. This regulatory support not only enhances the market's attractiveness but also fosters innovation as companies strive to meet compliance requirements while improving their operational efficiencies. The alignment of regulatory policies with market trends is likely to sustain the growth of the UV-curing system market in the coming years.

Technological Innovations in UV-Curing Systems

Technological advancements are playing a pivotal role in shaping the UV-Curing System Market. Innovations such as LED UV curing technology are gaining traction due to their energy efficiency and longer lifespan compared to traditional mercury lamps. The introduction of high-speed curing systems is enabling faster production cycles, which is particularly beneficial in high-volume manufacturing environments. Furthermore, the integration of automation and smart technologies into UV-curing systems is enhancing operational efficiency and reducing labor costs. As a result, the market is witnessing an influx of new players and products, contributing to a competitive landscape. The continuous evolution of UV-curing technologies is expected to propel market growth, with estimates suggesting a market size reaching several billion dollars by the end of the decade.

Rising Consumer Preferences for High-Quality Finishes

Consumer preferences are evolving towards high-quality finishes in products, which is significantly impacting the UV-Curing System Market. Industries such as furniture, flooring, and consumer electronics are increasingly adopting UV-curing technologies to achieve superior surface finishes that are both durable and visually appealing. The ability of UV-curing systems to provide quick curing times allows manufacturers to enhance productivity while meeting consumer demands for quality. As consumers become more discerning, the pressure on manufacturers to deliver high-quality products intensifies. This trend is likely to drive further investments in UV-curing technologies, as companies seek to differentiate their offerings in a competitive marketplace. The emphasis on quality and aesthetics is expected to be a key driver of growth in the UV-curing system market.