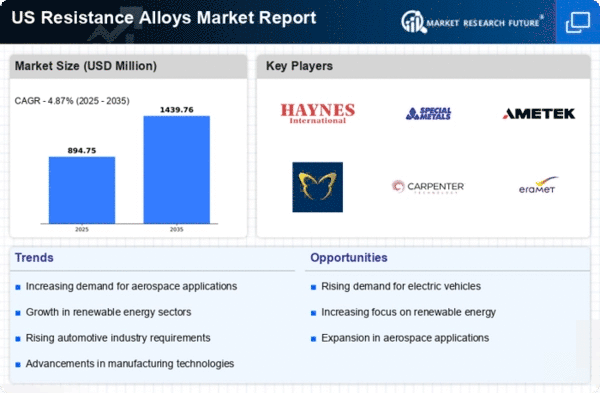

The resistance alloys market is characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand across various sectors, including aerospace, automotive, and energy. Key players such as Haynes International Inc (US), Special Metals Corporation (US), and Carpenter Technology Corporation (US) are strategically positioned to leverage their expertise in high-performance materials. These companies focus on innovation and product development, aiming to enhance their market share and meet the evolving needs of their customers. Their collective strategies, which include regional expansion and partnerships, contribute to a robust competitive environment that fosters growth and innovation.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. The market appears moderately fragmented, with several key players exerting influence over pricing and product offerings. This structure allows for a diverse range of products and services, catering to the specific requirements of various industries. The interplay between established companies and emerging players is likely to shape the market dynamics in the coming years.

In October Haynes International Inc (US) announced the launch of a new line of high-temperature alloys designed specifically for the aerospace sector. This strategic move is expected to enhance their product portfolio and strengthen their position in a rapidly growing market segment. By focusing on high-performance materials, Haynes aims to meet the stringent requirements of aerospace applications, which could lead to increased sales and market penetration.

In September Special Metals Corporation (US) expanded its manufacturing capabilities by investing in advanced production technologies. This investment is likely to improve efficiency and reduce production costs, allowing the company to offer competitive pricing while maintaining high-quality standards. Such enhancements in operational capabilities may provide Special Metals with a significant advantage in a market that increasingly values both quality and cost-effectiveness.

In August Carpenter Technology Corporation (US) entered into a strategic partnership with a leading aerospace manufacturer to develop next-generation alloys. This collaboration is indicative of a broader trend towards strategic alliances in the industry, as companies seek to combine resources and expertise to drive innovation. The partnership is expected to accelerate the development of new materials that meet the evolving demands of the aerospace sector, positioning Carpenter Technology as a key player in this niche market.

As of November current trends in the resistance alloys market include a strong emphasis on digitalization, sustainability, and the integration of AI technologies. These trends are reshaping competitive dynamics, as companies increasingly prioritize innovation over traditional price-based competition. Strategic alliances are becoming more prevalent, enabling firms to pool resources and enhance their technological capabilities. Looking ahead, the competitive landscape is likely to evolve further, with differentiation driven by technological advancements, supply chain reliability, and a commitment to sustainable practices.