Expansion of the Construction Sector

The US Polyester Coatings Market is poised for growth, largely due to the expansion of the construction sector. With the US economy showing signs of recovery, investments in residential and commercial construction are on the rise. According to the US Census Bureau, construction spending has increased steadily, with a year-on-year growth rate of approximately 4% in recent months. This surge in construction activity is driving the demand for durable and aesthetically pleasing coatings, particularly in architectural applications. Polyester coatings, known for their excellent weather resistance and color retention, are becoming increasingly popular among builders and architects. As the construction sector continues to flourish, the US Polyester Coatings Market is likely to benefit from heightened demand for high-performance coatings.

Rising Demand from Automotive Sector

The automotive industry is a significant driver of growth for the US Polyester Coatings Market. As vehicle manufacturers seek to enhance the aesthetic appeal and durability of their products, polyester coatings are becoming a preferred choice due to their excellent finish and resistance to environmental factors. The US automotive market is projected to witness a steady increase in production, with estimates indicating a growth rate of around 3% annually. This trend is likely to bolster the demand for high-performance coatings that can withstand the rigors of automotive applications. Consequently, the US Polyester Coatings Market is expected to benefit from this rising demand, as automotive manufacturers increasingly turn to polyester coatings for their vehicles.

Growing Demand for Eco-Friendly Coatings

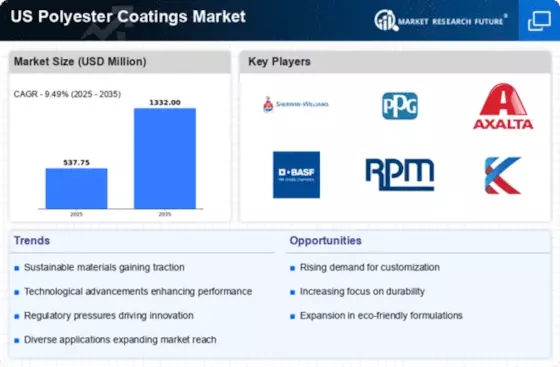

The US Polyester Coatings Market is experiencing a notable shift towards eco-friendly products, driven by increasing consumer awareness regarding environmental sustainability. As regulations tighten around volatile organic compounds (VOCs), manufacturers are compelled to innovate and develop low-VOC polyester coatings. This trend is further supported by the US Environmental Protection Agency's initiatives promoting sustainable practices. The market for eco-friendly coatings is projected to grow significantly, with estimates suggesting a compound annual growth rate (CAGR) of around 5% over the next five years. This growing demand for environmentally responsible products is likely to reshape the competitive landscape of the US Polyester Coatings Market, encouraging companies to invest in research and development to meet these evolving consumer preferences.

Increased Focus on Customization and Aesthetics

Customization and aesthetic appeal are becoming increasingly important in the US Polyester Coatings Market. As consumers seek unique and personalized products, manufacturers are responding by offering a wider range of colors, finishes, and textures in polyester coatings. This trend is particularly evident in sectors such as furniture, appliances, and consumer electronics, where visual appeal plays a crucial role in purchasing decisions. The ability to customize coatings not only enhances product differentiation but also allows manufacturers to cater to specific consumer preferences. As the demand for customized solutions continues to rise, the US Polyester Coatings Market is likely to see an uptick in innovation and product development aimed at meeting these diverse aesthetic needs.

Technological Innovations in Coating Applications

Technological advancements are playing a pivotal role in shaping the US Polyester Coatings Market. Innovations in application techniques, such as electrostatic spray and powder coating, are enhancing the efficiency and effectiveness of polyester coatings. These technologies not only improve the quality of the finish but also reduce waste and energy consumption during the application process. Furthermore, the development of advanced formulations that offer superior durability and resistance to chemicals is attracting a broader range of industries, including automotive and industrial manufacturing. As these technologies continue to evolve, they are expected to drive growth in the US Polyester Coatings Market, with manufacturers increasingly adopting these innovations to stay competitive.