Increased Focus on Automation

The industrial vision market is significantly influenced by the increasing focus on automation across various sectors. As industries strive to enhance productivity and reduce operational costs, the adoption of automated systems is becoming more widespread. Vision systems play a crucial role in automation by providing real-time data for decision-making and process optimization. According to recent data, the automation market in the US is expected to reach $200 billion by 2026, with a substantial portion allocated to vision technologies. This shift towards automation not only improves efficiency but also minimizes human error, thereby driving the demand for advanced vision systems in the industrial vision market.

Expansion of E-commerce and Logistics

The industrial vision market benefits from the expansion of e-commerce and logistics sectors. As online shopping continues to grow, the demand for efficient warehousing and distribution systems is increasing. Vision systems are being employed for inventory management, package sorting, and quality control in logistics operations. The logistics automation market is projected to grow by 15% annually, highlighting the need for advanced vision technologies to streamline operations. This trend suggests that the industrial vision market will continue to thrive as companies seek to enhance their logistics capabilities and improve overall efficiency.

Rising Quality Standards and Compliance

The industrial vision market is being propelled by the rising quality standards and compliance requirements across various industries. As manufacturers face increasing pressure to meet stringent regulations, the implementation of vision systems for quality assurance has become essential. These systems enable real-time monitoring and inspection, ensuring that products meet the required specifications. Industries such as automotive and pharmaceuticals are particularly affected, as they must adhere to rigorous quality control measures. The market for quality inspection systems is projected to grow by 10% annually, reflecting the critical role of vision technologies in maintaining compliance and enhancing product quality within the industrial vision market.

Growing Demand for Predictive Maintenance

The industrial vision market is witnessing growth due to the increasing demand for predictive maintenance solutions. Industries are recognizing the value of utilizing vision systems to monitor equipment health and predict potential failures before they occur. By integrating vision technologies with predictive analytics, companies can reduce downtime and maintenance costs significantly. The predictive maintenance market is expected to reach $12 billion by 2027, indicating a strong trend towards proactive maintenance strategies. This shift not only enhances operational efficiency but also extends the lifespan of machinery, thereby fostering the growth of the industrial vision market.

Technological Advancements in Imaging Systems

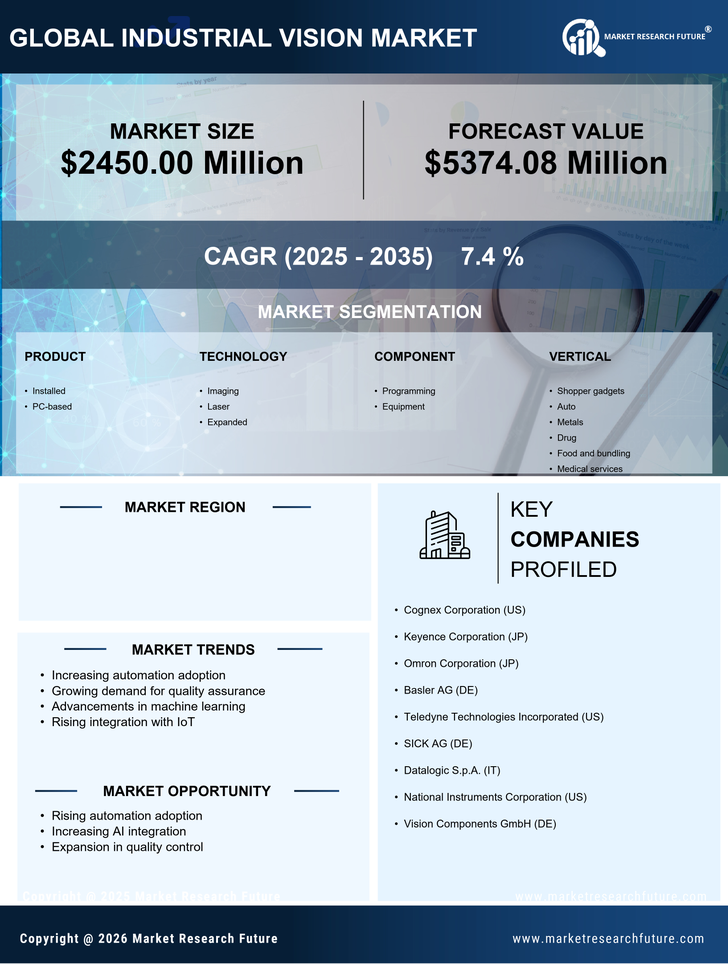

The industrial vision market is experiencing a surge due to rapid technological advancements in imaging systems. Innovations in camera technology, such as high-resolution sensors and advanced optics, are enhancing the capabilities of vision systems. Innovations in camera technology, such as high-resolution sensors and advanced optics, are enhancing the capabilities of vision systems. These improvements allow for more precise inspections and quality control processes, which are critical in manufacturing. The integration of 3D imaging and multispectral cameras is also becoming prevalent, enabling industries to perform complex analyses. As a result, the market is projected to grow at a CAGR of approximately 8% over the next five years, driven by the need for enhanced accuracy and efficiency in production lines. This trend indicates a strong demand for sophisticated imaging solutions within the industrial vision market.