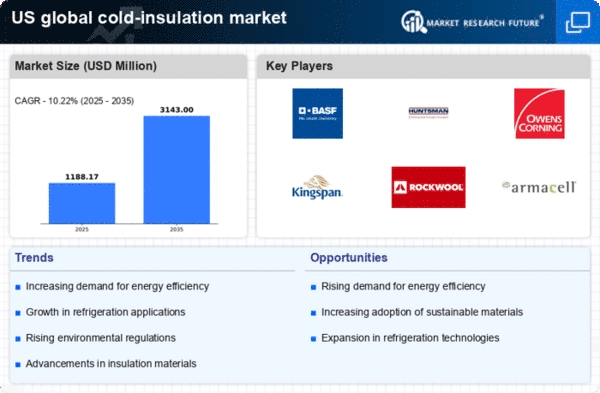

The global cold-insulation market is currently characterized by a dynamic competitive landscape, driven by increasing demand for energy-efficient solutions and stringent regulatory frameworks aimed at reducing carbon emissions. Key players such as BASF (DE), Huntsman Corporation (US), and Owens Corning (US) are strategically positioned to leverage innovation and sustainability in their operations. BASF (DE) focuses on developing advanced insulation materials that enhance energy efficiency, while Huntsman Corporation (US) emphasizes the integration of sustainable practices in its product offerings. Owens Corning (US) is actively pursuing partnerships to expand its market reach and enhance its technological capabilities, collectively shaping a competitive environment that prioritizes innovation and environmental responsibility.In terms of business tactics, companies are increasingly localizing manufacturing to reduce supply chain vulnerabilities and optimize operational efficiencies. The market structure appears moderately fragmented, with several key players exerting significant influence. This fragmentation allows for a diverse range of products and solutions, catering to various customer needs while fostering competition among established and emerging players.

In October BASF (DE) announced the launch of a new line of bio-based insulation materials, which are expected to reduce carbon footprints by up to 30%. This strategic move not only aligns with global sustainability trends but also positions BASF (DE) as a leader in eco-friendly insulation solutions. The introduction of these materials could potentially reshape customer preferences, driving demand for sustainable options in the market.

In September Huntsman Corporation (US) expanded its production capacity for polyurethane insulation in response to growing market demand. This expansion is significant as it enhances Huntsman’s ability to meet the needs of the construction and refrigeration sectors, thereby solidifying its market position. The increased capacity may also allow for more competitive pricing strategies, further enhancing its market share.

In August Owens Corning (US) entered into a strategic partnership with a leading technology firm to develop smart insulation solutions that integrate IoT capabilities. This collaboration is indicative of a broader trend towards digitalization within the industry, as companies seek to offer innovative products that provide real-time energy monitoring and efficiency insights. Such advancements could redefine customer engagement and product functionality in the cold-insulation market.

As of November current competitive trends are heavily influenced by digitalization, sustainability, and the integration of artificial intelligence in product development. Strategic alliances are increasingly shaping the landscape, enabling companies to pool resources and expertise to drive innovation. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition towards a focus on technological advancements, sustainability, and supply chain reliability. This shift underscores the importance of innovation as a key driver of market success.